Supplier Management

● Strategy: Prioritize suppliers' ESG and risk management by setting short- and mid-term key goals and specific actions to promote sustainable development of the value chain.

● Goals of 2030: Local procurement ratio exceeds 75% / Supplier on-site evaluation completed with a 100% success rate.

Leading the Industry Chain's Low-Carbon Transformation, Creating a Sustainable Supply Ecosystem

Suppliers are the important partners to CLC’s growth and burgeoning. Through management approaches, the evaluation mechanism, and guidance, we guide the up- and down-stream industrial chain to make continual improvement. Through the CLC e-procurement platform, we establish a stable supply chain ecosystem and team up with Taiwanese and global suppliers to create job opportunities and promote economic growth. Simultaneously, CLC continues to enhance sustainability management through supplier conferences and related evaluations, strengthening the sustainability of the supply chain to enhance the value-added of the paper industry.

Since initiating the Paper Industry Supplier ESG Conference in 2020, in 2023, we collaborated with 300 key partners again at the 4th CLC ESG Supply Chain Conference to discuss strategies for industry-wide low-carbon transformation, recognizing outstanding sustainable partners. In 2023, CLC also established the industry's only Carbon Neutrality Alliance, robustly accelerating the low-carbon transformation of the industry chain led by CLC, thereby enhancing Taiwan's paper industry competitiveness in the international market. Emphasizing risk management in the supply chain, we will progressively expand audits and evaluations of major overseas suppliers to promote sustainable development along the value chain.

Procurement Policy and Risk Management

We uphold a rigid, fair, and open transaction principle; abide by the laws and social norms; actively cultivate excellent suppliers, contractors, and alternative sources; conduct investigations and evaluations according to the related evaluation regulations, and establish the supplier graded management system to ensure the quality, delivery time, price, and after-sales service of supply sources. However, investigation will be conducted when suppliers have made significant changes. All CLC suppliers are requested to sign the “Supplier Code of Conduct”, to enhance supply risk management. From 2022, all new suppliers will also be required to sign the agreement. In 2023, we maintained cooperation with 269 major suppliers (annual purchase amount over NT$10 million).

.jpg)

.jpg)

CLC Supply Chain Conference Outlines Three-pronged Carbon Neutrality Strategy

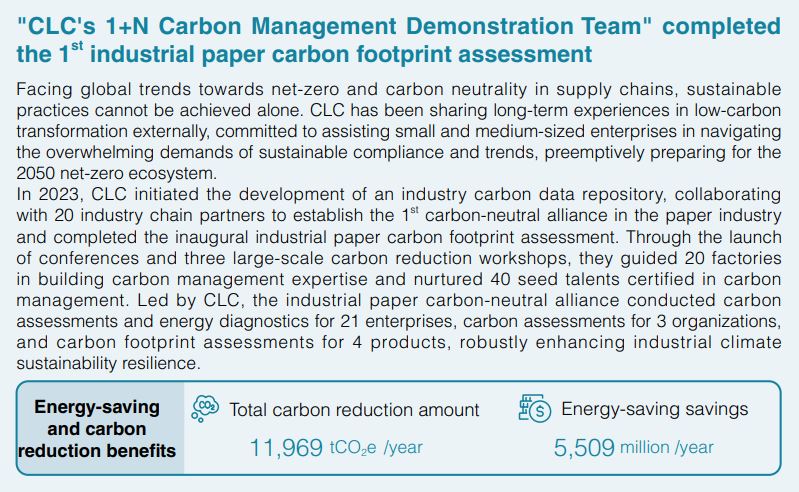

CLC's 1+N Carbon Management Demonstration Team" completed the 1st industrial paper carbon footprint assessment

Facing global trends towards net-zero and carbon neutrality in supply chains, sustainable practices cannot be achieved alone. CLC has been sharing long-term experiences in low-carbon transformation externally, committed to assisting small and medium-sized enterprises in navigating the overwhelming demands of sustainable compliance and trends, preemptively preparing for the 2050 net-zero ecosystem.

In 2023, CLC initiated the development of an industry carbon data repository, collaborating with 20 industry chain partners to establish the 1st carbon-neutral alliance in the paper industry and completed the inaugural industrial paper carbon footprint assessment. Through the launch of conferences and 3 large-scale carbon reduction workshops, they guided 20 factories in building carbon management expertise and nurtured 40 seed talents certified in carbon management. Led by CLC, the industrial paper carbon-neutral alliance conducted carbon assessments and energy diagnostics for 21 enterprises, carbon assessments for 3 organizations, and carbon footprint assessments for 4 products, robustly enhancing industrial climate sustainability resilience.

Supply Chain Management Policy

●Creation of a friendly workplace

●Enhancement of ESH management

●Emphasize sorting and recycling

●Grasp eco-friendly business opportunities

●Reduce impact on the environment

●Fulfill the responsibility as a citizen of the Earth

●Implement supply chain management

●Take more flexible procurement strategies

2. Exchange information on a regular basis, adapt to the global deployment of the Group, and share and understand the market development of important material sources.

3. Investigate all potential material sources transparently and openly and strive for stable sources of reasonably priced raw materials.

4. Perform joint procurement of important domestic and overseas raw materials for the Group to upgrade its competitiveness.

.jpg)

New Suppliers Development

CLC developed ”Supplier evaluation regulations” to ensure the equipment, service and product quality, delivery time, flexibility and price could meet the procurement and price policy of company. 100% of new suppliers in 2023 completed the environment and social evaluation.

Annual Suppliers Evaluation in 9 dimensions (including Climate Action)

To realize the sustainable supply chain ecosystem with partners together, we evaluate suppliers periodically according to the ISO procurement SOPs. Each year the procurement, technology, and requisition units will form a task force to comprehensively evaluate all suppliers having business with CLC to rate suppliers in 4 grades: Excellent, A, B, and C in terms of materials quality, service and coordination, environmental safety performance, delivery time cooperation, price, green supply, and ESG information disclosure. We also draw up management strategies for each grade to ensure the basic quality and supply capacity of suppliers.

The coverage rate of major supplier On-site Evaluation will reach 100% in 2030

In 2020, we began to perform "on-site evaluation" on suppliers of important materials highly connected to our products and processes ahead of the industry to optimize their risk management in the following 4 major aspects: R&D and process, environmental safety, procurement, and quality assurance, hoping to keep up with the industrial trends and meet our specifications. We also include 10% more suppliers for evaluation coverage ratio each year to achieve evaluation on all important suppliers by 2030.

In 2023, we completed on-site evaluations for a total of 55 suppliers, achieving a cumulative total of 211 over the past 4 years, meeting 68% of our target set for 2030. The evaluation results for 2023 were as follows: 45 suppliers rated as excellent, 10 rated as grade A, 0 rated as grade B, and 0 rated as grade C. To continuously enhance the sustainability capabilities of our supply chain, we plan and execute on-site evaluations and audits annually. We also optimize and refine evaluation criteria based on industry trends and the actual conditions of suppliers. For suppliers with lower evaluation scores, we assign specialists or engages experts to provide guidance, thereby collectively promoting the sustainable management of the industry chain.

.jpg)

Suppliers Orientation

To promote green procurement and reach the HSE consensus in supply chain partners, we actively arrange related education and training for suppliers. In 2023, we organized 8 sessions with the participation of 104 suppliers.

.jpg)

Support for Local Procurement Local Supplier Ratio was 2.9%

To pursue the stability and localization of the supply chain, we prioritize the use of local suppliers in Taiwan and have set a mid- and long-term goal of achieving a local procurement ratio of >75% by 2030. In addition to shortening delivery times and reducing transportation risks, this strategy helps diversify local sources of recycled materials, supports local businesses, and promotes regional prosperity. To adapt to our operational needs, we make rolling adjustments to the number of local suppliers and the amount of local procurement annually. In 2023, the proportion of local suppliers was 82.9%, a decrease from the previous year due to the addition of advanced overseas eco equipment suppliers for equipment upgrades. Nonetheless, the local procurement amount in 2023 accounted for 69.7% of total procurement, an increase of 3.3% from the previous year.

.jpg)