ESG: Climate change Action

CLC 65: Paper-driven Cross-disciplinary Sustainability Solutions

In 2024, CLC marked its 65th anniversary and continued to advance Paper-based Solutions (PbS) through innovation and 3R PLUS Total Resource Circulation Technologies. As one of the 1st TNFD Note 1 Early Adopter, CLC integrated multi-stakeholder resources and cross-sector collaboration to expand the scale and impact of circular sustainability, enabling a single sheet of paper to deliver environmental, ecological, and social benefits.

"Less is More' is the core of CLC's sustainability strategy. In addition to advancing Total-Citcular technologies and striving to safeguard the environment with minimal manufacturing consumption, we also foster creativity to strengthen the industry's carbon reduction resilience. By bringing together external partners and resources, we maximize our positive influence."

Emphasizing Nature-based Solutions, Expanding 3R PLUS Circular Economy Inuence

CLC advances S.M.A.R.T. carbon reduction manufacturing by reducing tree felling and planting secondary forests. Through continuous enhancement of circular technologies, CLC's Taiwan manufacturing chain achieves a leading rate of recovered paper and waste resource utilization, and has established the only household paper brand certified with FSCTM Recycled, Environmental Label, and Carbon Footprint Label. Since 2018, CLC has expanded circularity through innovation and R&D, building a food paper container recovering supply chain using paper-plastic separation technologies, processing over 50% of Taiwan's waste food paper container and delivering significant carbon reduction. CLC integrates agricultural and forestry resources with product, energy, and water cycles, launching the 3R PLUS Total Resource Circular business model to strengthen circular economy impact. CLC also developed 100% recovered eco weed control paper, certified as organic material by the Ministry of Agriculture, reducing farmland plastic residue and lowering organic cultivation import costs for small farmers through local materials.

*Note 1: TNFD (Taskforce on Nature-related Financial Disclosures)

Donated 10,000 kg of Organic Contract Rice to N early 1,000 Individual Recyclers

In line with the Group's 65th anniversary goals of "Nature Sustainability, Paper Towards Net Zero," CLC supported nature-friendly farming by developing eco weed control paper made from 100% recovered paper, addressing soil pollution from traditional plastic mulch and pesticide residues. CLC is promoting this solution for four major crop categories: fruit trees, vegetables, flowers, and specialty crops, to accelerate sustainable agriculture and decarbonization.

During the rice harvest, CLC mobilized its volunteer team to Dounan Township, Yunlin County, to inspect harvest results and exchange organic farming practices. CLC adopted 10,000 kilograms of contract-grown rice, sharing outcomes with employees and supply chain recyclers, and promoted food safety education through social welfare initiatives.

*CLC will continue to enhance the contract rice adoption project and expand sustainable agriculture efforts. For more information, please refer to the CLC website - Press Release 1

Plant for the Planet: Restoring Carbon Sink Value in Huisun Forests

Protecting forests is essential for preserving habitats of over 50% of known species and preventing the release of 30% of stored organic carbon, thereby mitigating global warming. CLC ensures all paper production avoids harm to primary forests by advancing recycled material and technologies, annually recycling over 1.6 million tonnes of recovered paper and establishing 21,000 hectares of secondary forest in Taiwan.

In response to increased wildfire risks from climate change, CLC implements sustainable forest and ecological restoration policies, focusing on soil carbon sequestration to enhance carbon reduction. CLC supports primary forest conservation and promotes integrated development of operational mills/plants and surrounding green belts.

For its 65th anniversary, CLC and the Academy of Circular Economy at National Chung Hsing University launched a restoration project for fire-damaged areas in Huisun Forest. On April 13, over 100 CLC employees, family members, and supply chain partners, led by Chairperson Jen-Ming Cheng and President Fuh-Jyh Jan, planted 500 saplings. The project applies NASA Landsat satellite monitoring and a six-year monitoring and maintenance plan to restore animal habitats and forest carbon sequestration lost to wildfires and to increase soil carbon storage.

*Local Atayal and Seediq communities participated in planting and future maintenance, supporting both ecological restoration and local employment. For more information, see the CLC website - Press Release 2

*Note 2: Using 1 tonne of recovered paper preserves 20 trees. Each hectare supports 1,500 trees. Using 1,600,000 tonnes of recovered paper conserves 21,333 hectares of secondary forest.

People-centered: Developing Green Collar and AI Competencies to Strengthen Corporate Sustainability and Resilience

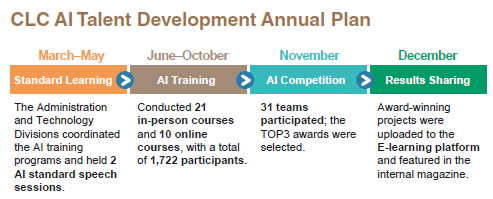

CLC implemented a 10-year talent development plan and established the CLC Talent Academy to systematically train internal instructors and build the smart papermaking 4.0 talent pool. In 2024, CLC increased employee training hours, holding 47 in-person courses with 1,878 participants. Of these, 9 AI-related courses were delivered in 21 sessions, accounting for nearly half of all training. A total of 105 training hours were completed, with 890 section chiefs and above participating. CLC advanced intelligent transformation across strategy, equipment, and talent management, focusing on production and sales capacity and carbon reduction, marking the Milestone Year of AI applications for low-carbon. CLC will continue to develop green and smart talent to enhance sustainable competitiveness.

Building a Diverse and Inclusive Workplace and Expanding the Green Talent Pool

CLC aligns talent development with corporate governance and sustainability planning. Internally, CLC implements a 10-year plan to train 300 internal instructors by 2030, increase average employee training to 48 hours, promote domestic and international job rotations, and encourage diversified career development. CLC has established a talent recommendation system and transparent feedback channels to strengthen international talent development and succession planning. Through the CLC Talent Academy's three frameworks—E-Learning platform, Total Productive Maintenance, and a company-wide best practice proposal system—CLC has improved operational and production efficiency, generating over NTD 1.2 billion in profit from 2021 to 2024.

Externally, CLC has established 31 paper libraries using 100% recovered paper, integrating experiential learning to raise environmental awareness among children. In 2022, CLC founded Asia's 1st Circular Economy Research Institute, focusing on agricultural and forestry resource recycling and natural carbon sink research. CLC launched CLC iPAS certification programs by connecting industry, government, academia, and research resources to enhance supply chain smart manufacturing competitiveness.

CLC advances industry-academia collaboration by offering internships, scholarships, and projects tailored to neighboring plant environments, including forestland restoration and biodiversity monitoring. CLC is committed to building a diverse, socially inclusive workplace and strengthening its international green talent pool to ensure long-term industry resilience and competitiveness.

Milestone Year of AI Applications: Integrating Manufacturing, Management, and Sales to Strengthen Smart Manufacturing Capabilities

In 2019, CLC launched Smart Papermaking 4.0, becoming the 1st paper company in Taiwan to implement intelligent production and sales, advancing low-carbon transformation. In response to rapid global AI technologies development and evolving sustainability trends, CLC designated 2024 as the Milestone Year of AI applications. CLC developed an internal GPT system to enhance administrative efficiency and HR service quality, and promoted smart factory transformation aligned with Industry 4.0, focusing on equipment integration, energy-saving and carbon reduction monitoring, and automation to address workforce structure challenges.

In 2024, CLC implemented 9 in-person AI application courses (21 sessions) and 10 online courses, training 1,722 employees (nearly 50%) to strengthen AI technologies understanding and application. CLC held an AI Application Competition with 31 participating teams to promote practical AI integration and cross-departmental collaboration.

The 1st prize team used AI to prepare business reports, tripling work efficiency. The 2nd prize team improved production efficiency in four areas with AI. The 3rd prize team applied AI to papermaking machine document management and automated safety and health certificate searches. CLC will continue investing in AI education and applications to support long-term low-carbon production and sales.

.jpg)

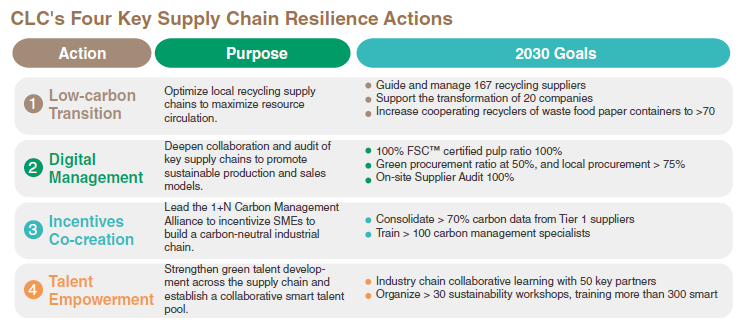

Four Key Resilience Actions: Building a Sustainable Net-zero Value Chain

Building and upgrading the industry talent pool is essential for international competitiveness in the era of sustainable low-carbon supply chains. CLC assessed supply chain transformation and implemented four resilience actions: Low-carbon, Digitalization, Incentives, and Empowerment. These actions supported supplier upgrades, enhanced local supplier resilience, expanded international order and nancing opportunities, and advanced the sustainable net-zero ecosystem.

Enhancing Industry Collaboration with 300 Key Partners to Advance Low carbon Smart Manufacturing Competitiveness

CLC identified tariff risks and industrial opportunities in the zero-carbon economy and in 2023 established a carbon database. CLC partnered with 20 supply chain companies to form the papermaking industry's 1st Carbon Neutrality Alliance and completed Taiwan's first industrial paper carbon footprint inventory, achieving an annual reduction of nearly 12,000 tonnes of carbon and saving over NTD 55 million in energy costs. In 2024, CLC launched the CLC iPAS Industrial Control Cybersecurity and Smart Manufacturing Supply Chain Program to build a talent pool for industrial control cybersecurity and strengthen digitalization and risk management in the paper industry. President Ching-Biao Chang emphasized that sustainability requires collaboration, and CLC continues to advance supplier engagement to ensure CLC's low-carbon products remain the preferred choice for global corporations under the net-zero trend. To accelerate the industry's upgrade toward low-carbon smart manufacturing, CLC is driving dual transformation— Net Zero Transformation and Smart Manufacturing—for 300 key supply chain partners, with four major sustainable resilience actions and over 15 action goals.

CLC led the industry's low-carbon and smart transformation, becoming the only company in Taiwan's paper sector to be included for three consecutive years (2022~2024) in the Global 200 Clean Companies (CLEAN 200) by Corporate Knights. In 2024, CLC received a management-level rating in the CDP Climate Change Questionnaire and was listed on the Supplier Engagement Assessment (SEA) A List. Since 2019, CLC has implemented Internet of Things Technologies for real-time equipment monitoring and intelligent inspections to enhance energy efficiency and carbon reduction.

In 2024, CLC established the Sustainable Supply Chain Program, integrating resources from industry, government, academia, and research institutions. In partnership with the Ministry of Economic Affairs, CLC launched the CLC iPAS Industrial Control Cybersecurity and Smart Manufacturing Supply Chain Program, aligned with Smart Production and Smart Networking and Industrial Control Cybersecurity certifications. The program combined lectures, practical training, and competency assessment, training nearly 70 interdisciplinary professionals to strengthen digitalization and risk management across the supply chain, enhancing smart manufacturing competitiveness.

.jpg)

.jpg)