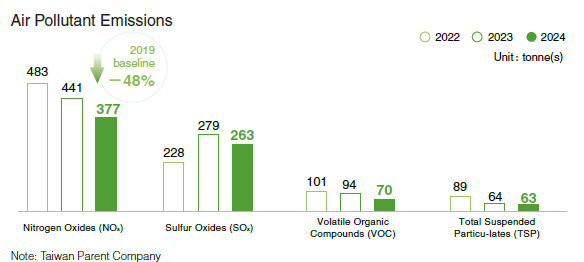

Air Quality Management

● Strategy: Reduce air pollutant emissions and improve air quality.

● Goals of 2030:

◆ Taiwan Parent Company target: 33% reduction in NOx emission concentration (baseline year: 2019)

◆ No violations or fines related to air pollution or odor anticipated

Strengthen Air Emissions Management to Ensure Compliance with Environmental Standards

CLC continuously strengthens air quality management by enforcing stricter controls and precise emission source monitoring to reduce air pollution. All major paper mills are equipped with continuous automatic air quality monitoring systems connected to regulatory authorities, ensuring transparent and compliant emission data. Regular inspections of boiler equipment and emission pipelines are conducted to maintain stable operations. CLC implements a three-stage air pollution management strategy, reducing emissions through source reduction and end-of-pipe treatment:

• Process Optimization: Continuously improve production systems to enhance energy efficiency and reduce pollutant emissions

• End-of-pipe Control: Installation of emission treatment equipment to enhance pollutant filtration and removal capacity

Air Pollution Control Facility Upgrades for Enhanced Air Quality

CLC upgraded equipment to reduce air pollution, including constructing an indoor coal yard at Houli Paper Mill in 2019 to control particulate emissions. In 2020, CLC added dust control equipment at coal bunker entrances and exits, installed water mist foam dust removal devices, and introduced a baghouse ash pneumatic conveying system. Multiple SCR units were installed to improve air quality. Biogas desulfurization equipment was installed at the Tayuan Paper Mill wastewater treatment plant, the G2 unit at Houli Paper Mill operated at reduced load, and high-quality coal was procured, significantly reducing SOx emissions.

In 2024, a plate heat exchanger was added to the desulfurization system at Tayuan Paper Mill to enhance exhaust gas treatment efficiency. In 2025, the company will proceed with the boiler denitrification system replacement at Houli Paper Mill to further strengthen air pollution control and optimize air quality.

*Note: SCR (Selective Catalytic Reduction) is a technology for removing NOx (nitrogen oxides) from flue gas.

1st Paper Company in Taiwan to Establish an Indoor Coal Yard

Indoor coal storage facilities reduce particulate emissions and comply with regulations for enclosed structures. CLC Houli Paper Mill and ChuPei Paper Mill completed construction of indoor coal yards. Coal silos are divided into 3 zones for separate storage by coal type, enabling allocation and transport based on boiler combustion characteristics. Regular pile turning is conducted to prevent spontaneous combustion.

1st Corrugated Container Company to Fully Replace Fuel Boilers with Natural Gas, Achieving Environmental and Operational Gains

Since 2013, CLC replaced all fuel oil boilers at box plants with natural gas boilers, completing the transition in 2020. This upgrade increased combustion efficiency by over 5%, reduced greenhouse gas emissions by 27%, nitrogen oxide emissions by 63%, and total suspended particulate emissions by 93%. These measures significantly reduced air pollutant emissions and fuel costs. CLC's air quality management performance attracted visits from industry, government, and academia, establishing the company as a benchmark in environmental management.

.jpg)

Strengthen Odor Control to Improve Plant Environmental Quality

CLC addressed plant odor issues through process and system optimization, achieving measurable results. Each unit identified odor sources and developed odor maps to target mitigation actions. High-efficiency air pollution control equipment was installed to reduce odors and pollutant emissions. In 2024, CLC implemented four major odor management measures and received no fines related to air pollution odors.

.png)