Healthy Workplace

● Strategy: OH&S Policy: Risk Management, Safety Work, Health Workplace

● Goals of 2030:

◆ Foster a health and safety culture by targeting a 5% YoY increase in participants in OH&S and health promotion activities and seminars starting from 2025

◆ Ongoing support for the implementation of ISO 45001 occupational health and safety management systems at new overseas plants

◆ Implementing Zero Workplace Accidents

CLC Safety and Health Policy

.png)

Optimizing Health and Safety Policy, Focusing on Systematic Risk Management, Safeguarding Employee Well-being

CLC established the ESH Promotion Committee in 2000 and implemented a health management system based on the ISO 45001 framework, covering employee healthcare and wellness with a focus on health protection, leisure and well-being, and physical and mental care.

In 2024, CLC enhanced its safety and health policy, establishing three core pillars: risk management, safe operations, and health protection. The updated policy is implemented through regular risk assessments, safety training, and equipment inspections to ensure workplace safety. Employee health management and emergency response capabilities are strengthened through health examinations, consultations, and emergency drills, supporting the goal of prevention over treatment.

CLC is committed to safeguarding employee well-being and workplace dignity by continuously enhancing occupational safety, health management, and integrating human rights into corporate governance. In 2024, the HQs conducted Human Rights Risk IdentificationNote, identified 3 key risk issues, and initiated the implementation of a Human Rights Due Diligence mechanism to strengthen institutional response and policy enforcement, aiming to create a safer and fairer work environment.

*Note: For the CLC Human Rights Risk Identification process, see Section 5.1 Human Rights Risk Identification in this report

Annual action plans are implemented by safety and health personnel, plant nurses, and occupational physicians at each CLC plant to advance health management and create a healthy workplace. By integrating health promotion and risk management, a comprehensive health protection system is established to ensure employees work in a safe and healthy environment.

.png)

.png)

Health Promotion Activities at Plants: +5% YoY Participation Target from 2025

CLC is implementing ongoing health promotion activities and enhanced care programs to advance workplace health, aiming for all sites to obtain the Healthy Workplace Accreditation form the MoHW. Short- and medium-term targets for participation have been set. In 2024, 114 health promotion activities and seminars were held, with 2,149 total participants.

Each CLC mill/plant has established an OH&S Committee comprising site supervisors, OH&S personnel, and other relevant staff. Labor representatives, elected by employees, accounted for 33.3%~63.6% of each committee and included production line workers, team leaders, section chiefs, TPM executive secretaries, and plant nurses. The OH&S Committee holds quarterly meetings to discuss and implement OH&S-related decisions and activities. CLC continues to support the implementation of ISO 45001 OH&S Management Systems at overseas sites. Vietnam Binh Duong Paper Mill, Binh Duong Plant, Viet Long Plant, Long An Plant, and Bac Giang Plant completed system implementation in 2023; Binh Gi Plant is actively introducing the system.

.png)

HSE Risk Assessment with a Total of 4,975 OH&S Proposals Received

CLC follows the ISO/CNS 45001:2018 management framework and PDCA cycle to establish EHS assessment criteria. Annual assessments of risks and opportunities are conducted, with improvement or control measures proposed and decided at management review meetings. Plant management representatives allocate resources as needed. When equipment or process changes, occupational accidents, or corrective actions for nonconformities occur, hazard identification and risk assessment are repeated.

To strengthen preventive management and continuous improvement, CLC identifies near-miss incidents as key risk indicators and tracks reporting records and corrective actions through its management system to reduce potential hazards. In addition, CLC promotes proposal-based improvements, encouraging employees to submit suggestions on operational safety and environmental issues. In 2024, a total of 4,975 safety and health proposals were submitted, and outstanding plants were recognized at the year-end performance review meetings.

In 2024, CLC Consolidated Company (Taiwan, Mainland China, Vietnam) reported 21 disabling employee injuries: 9 entanglements, 3 falls, 1 fall from height, 3 cuts, 2 crush injuries, 2 collisions, and 1 struck by falling object. No occupational diseases occurred. For non-employees, 4 disabling injuries were recorded: 1 fall from height, 1 collision, 1 cut, and 1 fall. No occupational diseases occurred. Targeted improvement measures were implemented to advance toward a zero-accident workplace:

.jpg)

In 2023, 14 employee disability injuries were reported (Taiwan, China and Vietnam), and pinch hazard and fall was the main type of occupational injury. We also actively implement improvement procedures to move forward zero accidents:

.png)

.png)

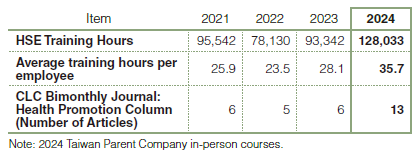

To strengthen real-time tracking of occupational safety and health regulations, CLC mills/plants implemented safety and health education and training plans. Employees participated in external seminars and training courses, while senior staff and external experts with practical experience in occupational safety regulations delivered lectures and conducted on-site diagnostics to enhance understanding of relevant laws and key implementation points. In 2024, the average safety and health training hours per employee reached 35.7 hours, increased 7.6 hours from 2023 (Taiwan Parent Company); in the consolidated company, the average was 26.9 hours.

Since 2021, CLC has published 30 articles in the Health Promotion Column of its Bimonthly Journal, focusing in 2024 on stress relief and insomnia. In 2024, 13 activities— including stress management courses and psychologist-led sessions—recorded 495 total participants. Practical stress relief methods were shared to support employee physical and mental health and improve quality of life and work efficiency.

Prevention and Management of Hypertension, Hyperglycemia, and Hyperlipidemia

With increasing rates of dining out and sedentary lifestyles, unbalanced diets and obesity have become major health concerns, highlighting the importance of weight management. CLC promotes employee health through low-oil, low-salt meals, encourages exercise and healthy habits, and continues to subsidize diverse clubs. In 2024, 25 sports clubs accounted for 95% of all employee clubs, fostering a culture of physical activity.

In alignment with the governments "Three Highs" (hypertension, hyperglycemia, hyperlipidemia) prevention policy, CLC monitors employee waist circumference and BMI as key chronic disease risk indicators and conducts annual follow-up analyses after health checkups. In 2024, 61.6% of employees in the Taiwan area were overweight or obese, exceeding the national average note. These employees were classified as a "Three Highs Risk Group" and receive regular health tracking and professional consultations. CLC continues to implement the "Wellness Weight Management Program" and "Stay Away from the Three Highs" health seminars, promoting the "Five Health Strategies"—regular exercise, balanced diet, emotional well-being, adequate sleep, and avoidance of smoking and alcohol—to reduce chronic disease risk and strengthen employee health awareness and self-management.

*Note: According to the Health Promotion Administration, Taiwan's adult overweight and obesity rate reached 50.8% in 2024.

The company conducts regular employee meal satisfaction surveys to optimize food quality and nutrition, implements cancer prevention and screening programs, promotes influenza vaccination, and provides timely health checkups and preventive measures to enhance employee health and overall health management performance.

.png)

.png)

.png)

Enhancing the Management and Ef ciency of Visits by External Units of HSE

We constantly optimize OH&S management by implementing an electronic ESH mill/plant visit response system to provide real-time and accurate information to ESH personnel and management, enhancing information sharing and management efficiency. There were 141 times of the ESH mill/ plant visits in 2024.

Contractor Management

CLC established the Contractor ESH Management Guidelines to strengthen contractor safety management and protect operational safety, contractor personnel, and equipment. The ChuPei Paper Mill holds the Annual Outstanding Contractor Selection Event to promote contractor compliance with company policies and improve workplace safety. In 2024, CLC delivered safety and health training to contractors 9,055 times, totaling 5,763 hours.

• Select and verify qualified contractors to undertake contracts.

• Sign the OH&S and environmental management undertaking.

• Hold consultative organization meetings to publicize hazard factors required notification for in-house operation.

• Perform plan entry control and apply for safe work permit.

• Implement in-house construction control and abide by in-house OH&S management regulations.

• Work safety check points: hot work, work at height, lifting/hoisting, risk management, cutting. • Publicize the electrical equipment management regulations.

Cross-factory Audit and OH&S Rating

Each mill/plant establishes annual OH&S goals and performance indicators in accordance with the OH&S management system. The HQs Health, Safety & Environment Department conducts cross-factory audits and annual mill/ plant ratings to monitor implementation, consolidates results for management decision-making, and sets goals and indicators for the following year. Dynamic management processes and OH&S evaluations facilitate cross factory and cross-division learning, strengthening the OH&S management system. Irregular OH&S inspections are also conducted at the factories in Vietnam, covering on-site 5S management, environmental management, and OH&S system operations, with overseas audits enhancing implementation. In 2024, we performed cross-factory OH&S audits on Corrugated Container Division at 7 mills and conducted annual OH&S rating on Containerboard Division, Household Products at 4 mills/plants.

Comprehensive Health Protection: CLC Digitalization Health Management System Platform

CLC independently developed the "CLC Health Management Platform" for real time tracking of high health-risk employees, with analysis and improvement recommendations provided by plant nurses and occupational physicians.

|

Heath Inspection |

We value the mental and physical health of employees. Every new employee must submit a physical examination report, and active employees must take the annual health checkup. For employees working in special work environments, we provide special health checkups (e.g. noise, dust, and ionized radiation examination). Cases requiring management and follow-up as determined by the physician are managed according to the protection plan, with employees provided sufficient information for further medical attention. • In 2024, 3,568 employees participated in general health checkup, with an achievement rate of 99.4%; and 1,148 employees took the special health checkup. Medical staff provided health guidance and consultations to employees with abnormal results. • Since 2021, Dr. Guan Tang Li has served as medical director, providing weekly consultations on major medical and health care issues. |

|

Improving Operation Environment |

Besides improving the ventilation equipment, cooling systems were installed in key work areas to enhance workplace comfort. |

|

Protecting Respiratory Health Protection: Companyside Smoking Ban , Smoking Cessation Classes and Competitions |

• Promoted a smoke-free workplace across all sites to create a safe and healthy environment and reduce employee exposure to 2ndhand smoke. • Since 2020, smoking cessation classes have been offered to provide professional support and encourage employees to participate. • Since 2023, the Smoking Cessation Competition has been held. Through carbon monoxide testing, peer support and prize recognition, to enhance employees' motivation to quit smoking. |

|

Health Promotion |

We promote health management and health promotion activities to build a healthy workplace. In 2024, we held 114 health promotion activities and seminars, with 2,149 participants. |

|

Health Protection |

In accordance with the OH&S Act, stress management seminars, core muscle exercise sessions, ergonomics hazard prevention seminars, and on-site guidance are arranged to address overwork, maternity, ergonomics, workplace violence, and respiratory protection, thereby enhancing health protection. |

Health Promotion Achievements Certi ed by 3 Major Organizations

In 2024, we promoted health initiatives and seminars on weight management, cancer prevention, and influenza vaccination, and enforced a smoke-free policy across all facilities. Preventive measures, including written assessments, were also implemented to address potential physical or mental harm during work, ensuring comprehensive protection of employee health.

CLC promoted work-life balance by establishing sports facilities in 11 mills/plants and fully subsidizing employee clubs for participation in health and leisure activities. Since 2020, CLC has partnered with the Sports Administration's Sports Calendar Platform to publicize events and competitions, actively creating a healthy and happy workplace.