Energy Management

●Strategy: Company-wide participation to improve energy efficiency, implement carbon reduction, and advance green production. Actions include supporting renewable energy development, increasing alternative fuel utilization, and reducing dependence on fossil fuels.

● Goals of 2030:

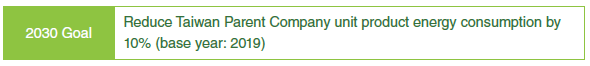

◆ Taiwan Parent Company targets a 10% reduction in unit product energy consumption (base year: 2019)

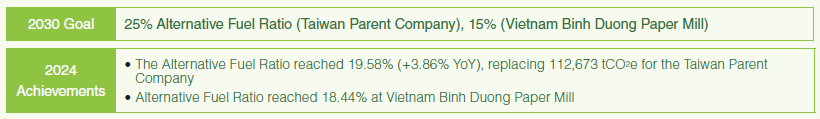

◆ Alternative fuel ratio:25% (Taiwan Parent Company);> 15% (Vietnam Binh Duong Paper Mill)

◆ Continue to expand renewable energy facilities at suitable sites

Digitalization of ISO 50001 Smart Management to Enhance Green Energy Efficiency

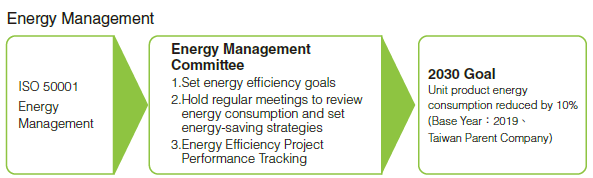

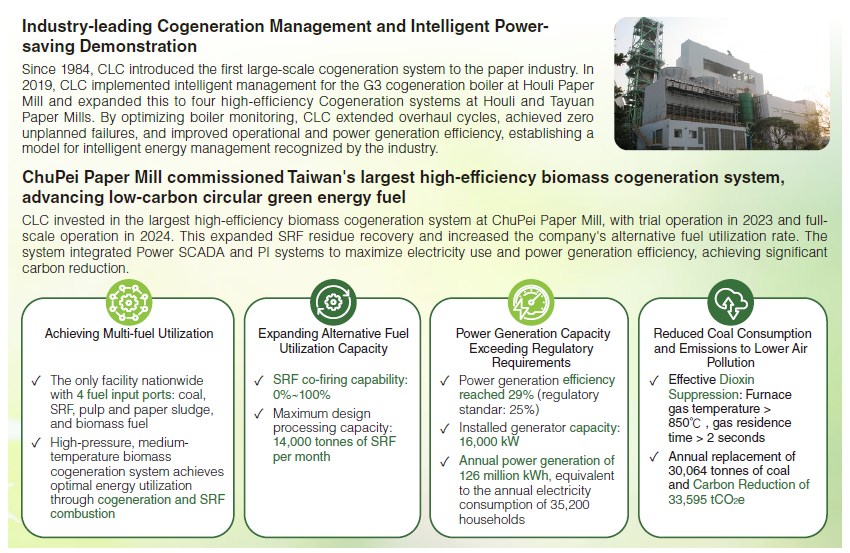

CLC implemented the ISO 50001 energy management system across all mills/plants, established energy management mechanisms, and regularly reviewed energy efficiency and energy-saving targets. To meet the annual 1% energy-saving commitment, each mill/plant developed specific energy-saving plans, including high-efficiency cogeneration systems, renewable energy installations, and equipment optimization. Smart systems were introduced to enhance carbon reduction performance and support the transition to a new low-carbon & green energy paper company.

CLC implemented the ISO 50001 energy management system in the Paper Division in 2013 and extended it to all Taiwan sites in 2015. A cross-departmental Energy Management Committee was established to set energy-saving targets, regularly review energy consumption, monitor project performance, share energy-saving technologies, and recognize achievements. The committee encouraged employees to identify energy-saving opportunities and improve resource efficiency. In 2022, CLC began implementing the ISO 50001 energy management system at overseas sites. In 2024, the Vietnam Binh Duong Plant and Bac Giang Plant obtained certification. CLC will continue to expand the system to overseas sites, conduct annual verifications, and advance intelligent energy management.

Carbon Reduction Initiatives

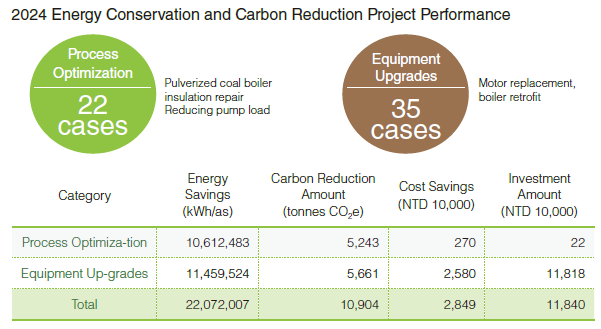

A total of 537 energy-saving projects have been implemented in 2024 and continuously improving energy efficiency

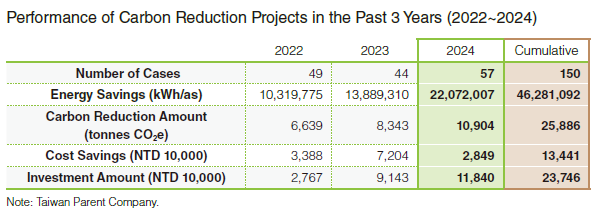

CLC enhanced energy efficiency by utilizing ISO 50001 energy management, intelligent controls, and cross-plant benchmarking to optimize paper machine operations. In 2024, CLC invested NTD 118.23 million in 57 energy-saving projects, including process improvements, equipment upgrades, and energy management. These initiatives saved 22,072,007 kWh of electricity (79,458.34 GJ), reduced CO2e emissions by 10,904 tonnes, and lowered energy costs by NTD 28.49 million. From 2013 to 2024, CLC completed 537 energy-saving projects, achieving cumulative electricity savings of 127,970,000 kWh and carbon reduction of 88,241 tonnes CO2e.

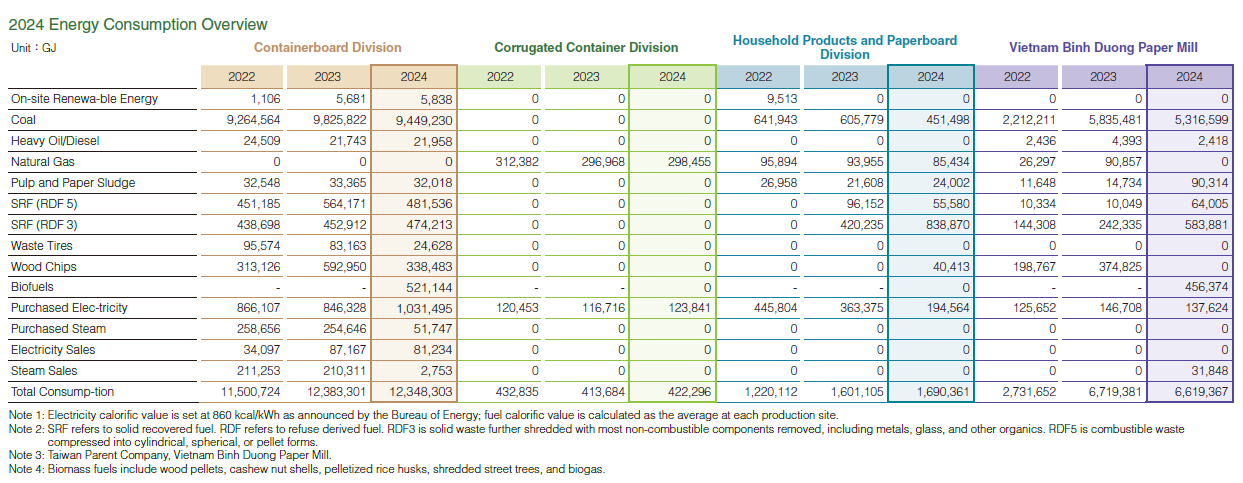

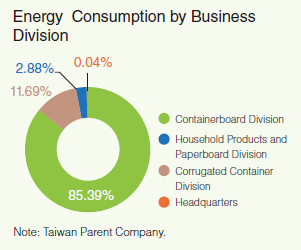

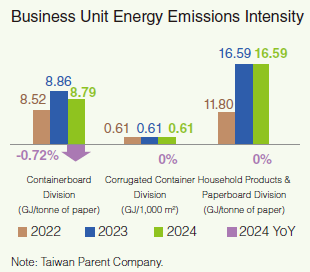

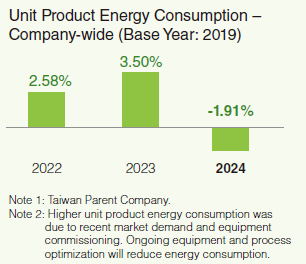

In 2024, the energy emission intensity of the containerboard division decreased by 0.72% to 8.79 GJ/tonne of paper. The Household Products & Paperboard Division and Corrugated Container Division maintained energy emission intensities at 16.59 GJ/ tonne of paper and 0.61 GJ/ thousand m², respectively. Unit product energy consumption decreased by 1.91% compared to the 2019 baseline, falling short of the 5% reduction goal due to increased energy use from market demand and equipment commissioning. CLC will continue to optimize equipment and processes to reduce energy consumption.

*Note: The energy improvement rate for each plant, compared to the base year, was weighted by each plant's share of total energy consumption (in GJ). The company-wide improvement rate was calculated as the sum of each plant's improvement rate multiplied by its share, and then converted to unit product energy consumption. A positive improvement rate indicates a decrease in unit product energy consumption; a negative rate indicates an increase. All energy values were standardized to GJ.

Accelerate Renewable Energy Development and Green Energy Opportunities

Increase Renewable Energy Capacity, Achieve Green Energy Targets Ahead of Schedule for Major Electricity Users

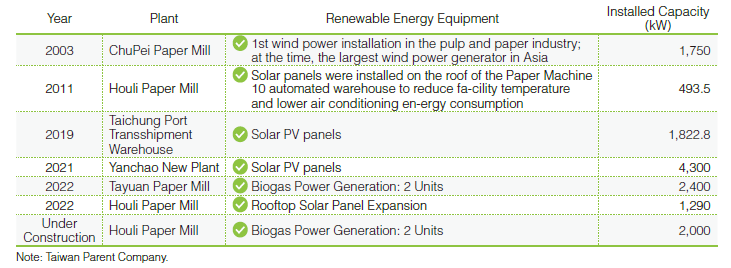

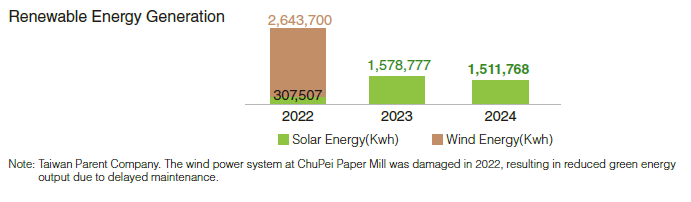

CLC installed wind, solar, and biogas renewable energy facilities based on each plant's geographic and production characteristics. By 2022, total renewable energy installed capacity in Taiwan reached 12,056 kW, nearly double that of 2020. In 2023, Houli Paper Mill expanded solar installations and launched a biogas project. ChuPei Paper Mill and Houli Paper Mill achieved the regulatory requirement for major electricity users ahead of schedule, reaching 10% renewable energy installed capacity before 2025 to accelerate low-carbon transition.

Sole industry holder of both wind and solar renewable energy certi cates, with a total of 14,087 certi cates accumulated

Since 2003, CLC has expanded renewable energy adoption, becoming the first paper company in Taiwan to obtain wind renewable energy certificates in 2017 and the only one to hold both wind and solar renewable energy certificates after acquiring solar certificates in 2023. The wind power system at ChuPei Paper Mill was damaged in 2022, limiting green energy output due to delayed repairs, but was restored in March 2025. As of the end of 2024, CLC had obtained 11,927 wind renewable energy certificates and 2,160 solar renewable energy certificates, totaling 14,087 certificates, equivalent to the annual electricity consumption of 3,913 households (based on Taipower's average monthly household electricity consumption of 300 kWh), demonstrating progress in low-carbon transition.

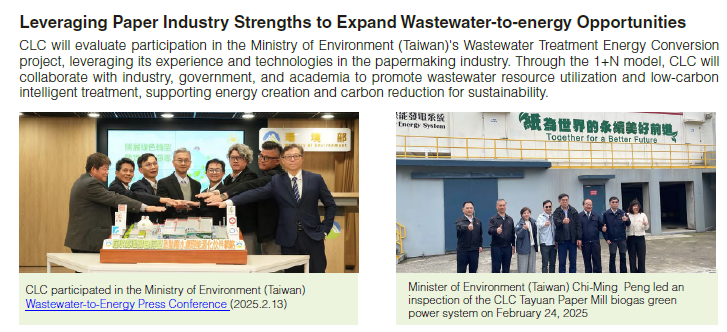

Waste-to-Energy: Biogas Power Generation for Sustainable Green Electricity

In 2022, CLC Tayuan Paper Mill commenced commercial operation of two 1,200 kW gas engine generators. In 2024, power generation reached approximately 11.5 million kWh, achieving a carbon reduction of 5,700 tCO2e. Tayuan Paper Mill also installed a waste heat recovery boiler, converting generator exhaust into 6,200 tonnes of steam annually for use in paper production. CLC plans to install two 2,000 kW biogas power units at Houli Paper Mill, with estimated annual generation exceeding 10 million kWh and a carbon reduction of over 5,200 tCO2e.

Accelerating Low-carbon Circular Alternative Fuel Adoption for Net Zero Transition

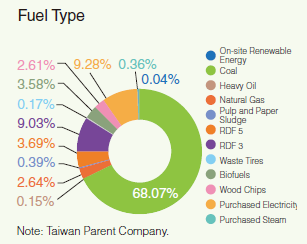

98% of Taiwan's energy is imported. To improve energy efficiency and reduce fossil fuel dependence, CLC develops alternative fuels by utilizing process residues and applying technologies to increase both quantity and quality, thereby raising the utilization rate of alternative fuels.

Establishment of Agricultural and Forestry Material Resource Taskforce to Advance Circular Alternative Fuels

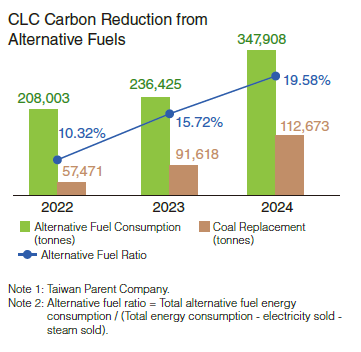

CLC's Taiwan Parent Company set a 25% alternative fuel ratio target for 2030. In 2022, the Climate Change and Circular Economy Office established the Agroforestry Material Resource Utilization Taskforce to lead R&D on alternative fuel technologies and circular resource utilization, ensuring stable domestic and international agroforestry residual material supply and supporting the development of a sustainable biomass material supply ecosystem. Vietnam Binh Duong Paper Mill set a medium- and long-term target of 15% alternative fuel use to reduce fossil fuel consumption.

2024 Achievements:

• Expand domestic biofuel processing to include street trees and waste wood

• The alternative fuel ratio in Taiwan reached 19.58% (+3.86% YoY), replacing 112,673 tonnes of coal

• Vietnam Binh Duong Paper Mill reached an alternative fuel ratio of 18.44%