Water Management

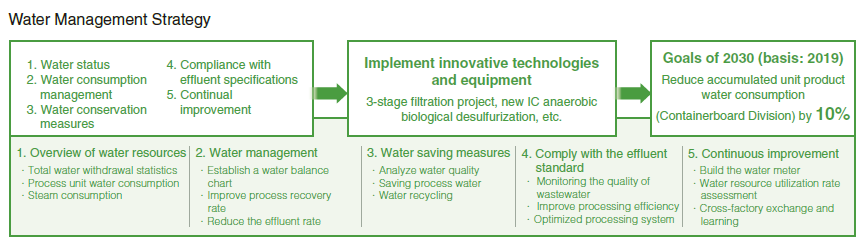

● Strategy:Enhance wastewater treatment and process water efficiency.

● 2030 Goal:

◆ The containerboard division targets a 10% reduction in unit product water consumption (base year: 2019)

◆ Enhance water conservation potential and recycled water volume

Value Water Resources

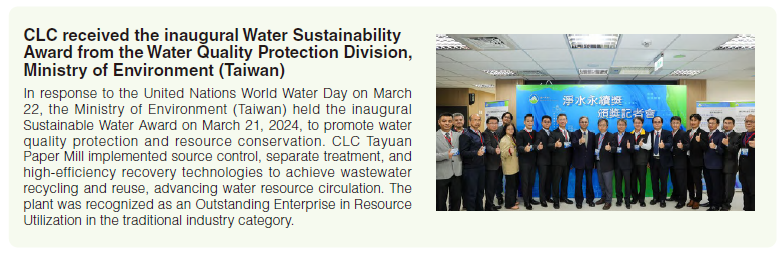

Resources are critical to the papermaking industry. When selecting production sites, CLC evaluates water sources based on regulatory requirements, long-term business needs, and local community water demand to ensure a balance between operations and regional water sustainability. CLC conducts risk assessments in accordance with ISO 14001, sets internal water control standards exceeding legal requirements, and ensures compliant water discharge.

2024 Achievements: 20.7% reduction in water consumption, record-high recycled water usage

CLC continues to upgrade water resource management by expanding water sources, strengthening prevention and control, and implementing Water conservation solutions to improve resource efficiency. CLC has developed a digital water resource PDCA management system to enhance management accuracy:

• Real-time monitoring: Hourly tracking of well water and each unit's water consumption to ensure autonomous management

• Water rights alert: The system issues real-time notifications when well usage reaches 90% of the allocated quota

• Abnormal Usage Monitoring: Automatically notifies the unit to address abnormal water usage

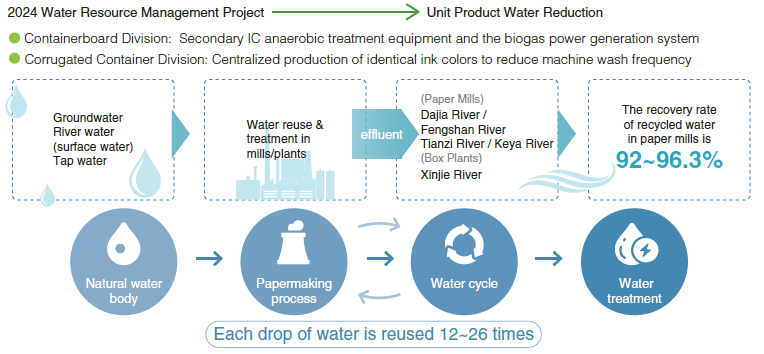

Maximizing Water Ef ciency: Recycled up to 26 Times, 96.3% Recovery Rate

In 2024, CLC invested NTD 392 million in water resource optimization and facility upgrades to further enhance water treatment efficiency upon project completion.

• Houli Paper Mill: planned to install anaerobic treatment facilities and a biogas power generation system; added a 3rd-stage treatment system to enhance water purification capacity • Tayuan Paper Mill: completed trash rack renovation to improve preliminary wastewater treatment efficiency

• Tayuan Box Plant: implemented a wastewater optimization project

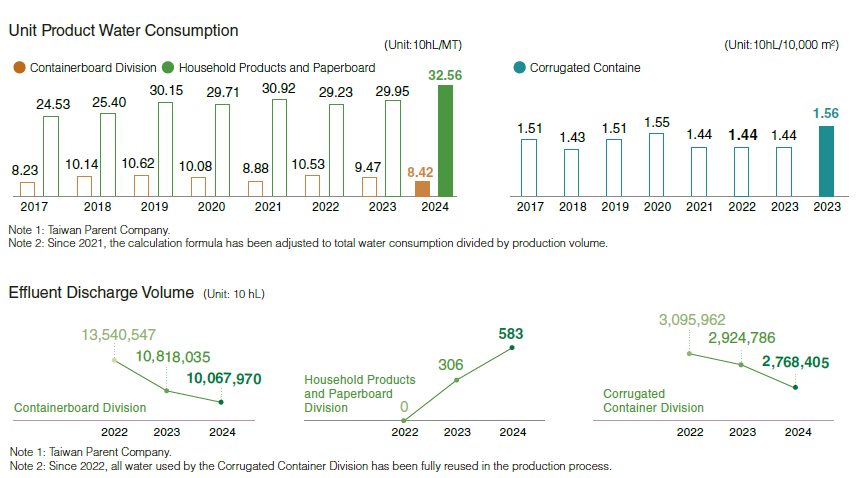

CLC achieved further improvements in water conservation in 2024. Unit product water consumption for industrial paper was 8.42 kiloliter/tonne of paper, a reduction of 11.08% from the previous year and 20.7% from the 2019 baseline, surpassing the original 5% reduction goal. Recycled water accounted for 17.69% of total water withdrawal in 2024 (+ 5.85% YoY), reaching a new high.

Internal water conservation measures are implemented and wastewater classification and discharge management are strengthened, focusing on process water conservation and recycling. All mills/plants are equipped with wastewater treatment systems and 24-hour water quality monitoring to ensure regulatory compliance. CLC manages process water usage to optimize wastewater treatment efficiency and support ecological balance and biodiversity.

Process water sources at CLC include groundwater, river water, and tap water. Plants manage water resources through rainwater recycling systems, white water recycling, ultrafiltration, and effluent water recycling to enable tiered management, recycling, and reuse, reducing consumption and maximizing water use efficiency. Annual water balance data are completed in accordance with Water Resources Agency regulations, and some paper mills have implemented smart water meters for real-time monitoring and control of water usage.

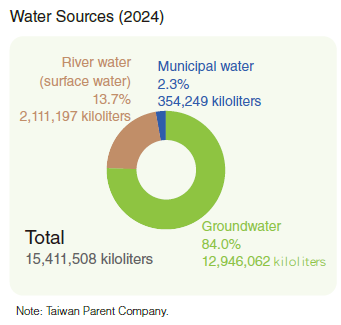

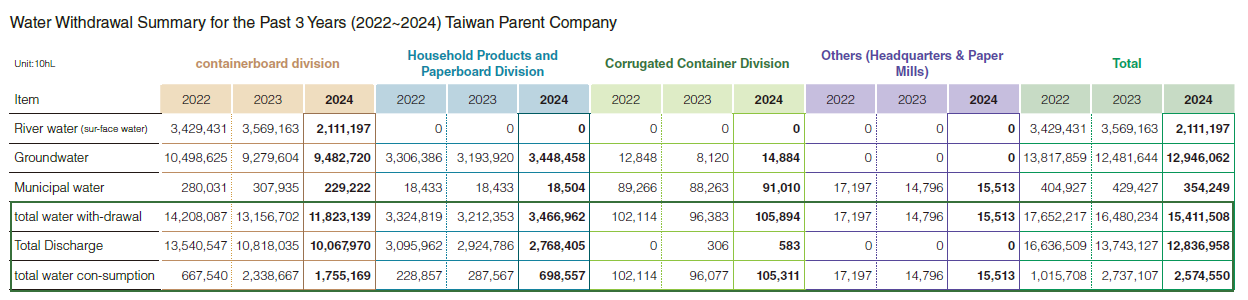

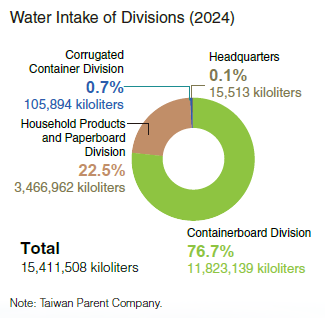

In 2024, the Taiwan Parent Company's total water withdrawal was 15,411 million liters, with surface water and groundwater accounting for 97.7% and tap water 2.3%. This was a decrease of 1,068 million liters from 2023. Total water consumption was 2,575 million liters. Water source management followed Water Resources Agency indicators, and water use was reduced in accordance with government regulations during supply restrictions. CLC's sites in Taiwan, Mainland China, and Vietnam were not located in areas of significant water stress.

CLC's water sources are located in areas with low water stress, with none in high-stress regions. In response to reduced municipal water supply or zoned outages, CLC implements several measures, including: (1) Adjusts tap water usage and increases effluent recycling and reuse in production, (2) Substitutes fresh water with recovered effluent, (3) Optimizes process management—including papermaking and printing schedules and water conservation models—to reduce water dependency and enhance operational resilience.

Effluent

All CLC mills/plants are equipped with water treatment systems. The Containerboard and Household Products and Paperboard Divisions use biological treatment and regularly monitor effluent quality to ensure compliance with standards, and continue to implement the wastewater plant QC-Recorder to optimize water treatment operations. The Corrugated Container Division applies physical and chemical treatment and recycles treated wastewater for process rinsing and starch preparation, significantly reducing water consumption.

.jpg)

Water Resource Conservation

CLC supported SDGs 6 "Clean Water and Sanitation" by adopting 80 public restrooms in Taiwan and implementing water resource conservation initiatives. Tayuan Paper Mill and Hsinchu Paper Mill adopted nearby river basins, conducted monthly river inspections, and regularly monitored water quality. Employees participated in river cleanup activities every 6months. Hsinchu Paper Mill and local residents established the Water Environment Patrol Team to patrol and maintain the Keya Creek basin. CLC participated in the "Tamsui River Pact—Do One Thing for the Tamsui River" initiative by implementing green procurement, adopting parks for biodiversity, and promoting water conservation. To support Taiwan's 2050 Net Zero Vision, the government introduced 12 key strategies for the 2025 Net Zero Transformation, including "Green Lifestyle." In 2024, CLC organized activities to encourage employees to take concrete actions to mitigate climate change through changes in daily habits and behaviors.