Supplier Management

● Strategy: Focus on supplier sustainability and risk management by setting short- and medium term targets and implementing action plans to advance value chain sustainability.

● Goals of 2030:

◆ Implement ESG risk assessment and management, obtaining valid carbon data from over 70% of key suppliers

◆ Expansion of Overseas Supply Chain Audits

◆ Supply chain sources are diversified, with no single supplier exceeding 50% of total supply

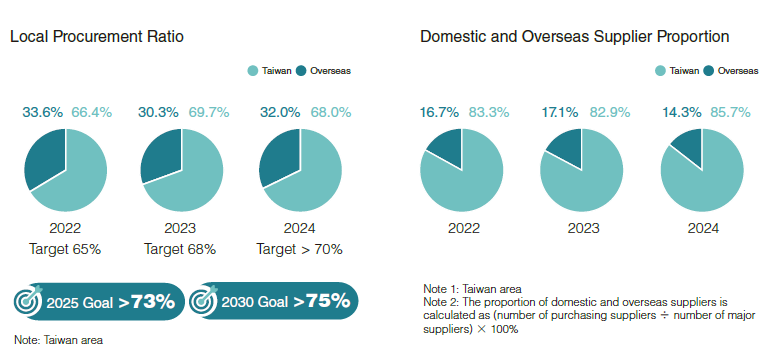

◆ Local procurement exceeds 75%

◆ Local procurement volume surpassed industry average

◆ Organize Sustainable Supply Chain Conferences and supplier EHS training to enhance supply chain resilience

◆ Strengthen green talent development across the supply chain and establish a collaborative smart talent pool

Responsible Supply Chain: Co-creation of Sustainable Value

Supplier partners are integral to CLC's operations. Through responsible supply chain management, CLC reduces risks and ensures product quality. CLC has established supply chain management policies, evaluation mechanisms, and guidance programs to drive continuous improvement. The online procurement platform connects domestic and global suppliers, supporting employment and economic growth. CLC holds sustainable supply chain conferences and conducts supplier evaluations to strengthen collaboration and advance supply chain sustainability. CLC was recognized on the A List of the CDP Supply Chain Engagement Assessment.

Since 2020, CLC has held the Sustainable Supply Chain Conference five times, collaborating with 300 key suppliers on low-carbon transition strategies. In 2023, CLC established the first Carbon Neutrality Alliance in the paper industry to accelerate supply chain decarbonization. In 2024, CLC launched the CLC iPAS Industrial Control Cybersecurity and Smart Manufacturing Supply Chain Program to strengthen digitalization and risk management. CLC expanded audits and evaluations of major overseas suppliers and, in 2024, conducted a climate questionnaire for key Tier 1 suppliers to assess low-carbon transition status and build a carbon data database to support net-zero targets.

Procurement Policy and Supplier Risk Management

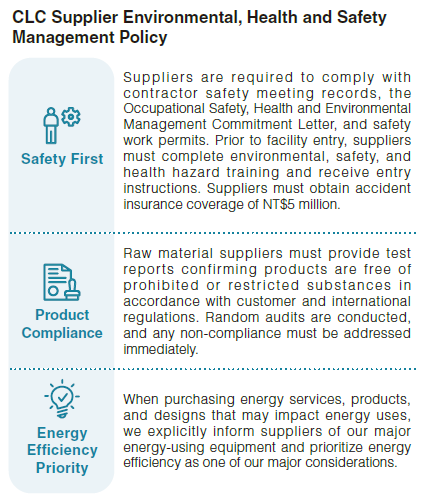

CLC adheres to strict, fair, and transparent trading principles, complies with regulations, and develops qualified suppliers, contractors, and secondary sources to ensure supply chain stability and competitiveness. Supplier surveys and evaluations are conducted according to established procedures. The Supplier Tiered Management System ensures supply sources meet requirements for quality, delivery, price, and after-sales service. In the event of major supplier changes, CLC immediately conducts reassessment to mitigate risk. All major suppliers and new partners are required to sign the Supplier Code of Conduct, which covers health and safety, labor conditions, environmental protection, energy conservation and carbon reduction, energy efficiency, and restricted substances, ensuring supply chain compliance and sustainability.

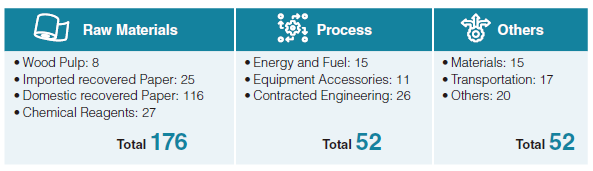

In 2024, CLC maintained partnerships with 280 major suppliers with annual transactions exceeding NTD 10 million, covering raw materials, processes, energy, chemicals, and equipment engineering.

Supply Chain Management Policy

●Creation of a friendly workplace

●Enhancement of ESH management

●Emphasize sorting and recycling

●Grasp eco-friendly business opportunities

●Reduce impact on the environment

●Fulfill the responsibility as a citizen of the Earth

●Implement supply chain management

●Take more flexible procurement strategies

2. Exchange information on a regular basis, adapt to the global deployment of the Group, and share and understand the market development of important material sources.

3. Investigate all potential material sources transparently and openly and strive for stable sources of reasonably priced raw materials.

4. Perform joint procurement of important domestic and overseas raw materials for the Group to upgrade its competitiveness.

CLC Supply Chain Evaluation Mechanism

Supplier Development and Assessment

CLC implemented the Supplier Evaluation Procedures to ensure timely raw material supply and maintain supply chain competitiveness. In 2024, 100% of new suppliers completed environmental and social responsibility assessments, fulfilling sustainable procurement requirements.

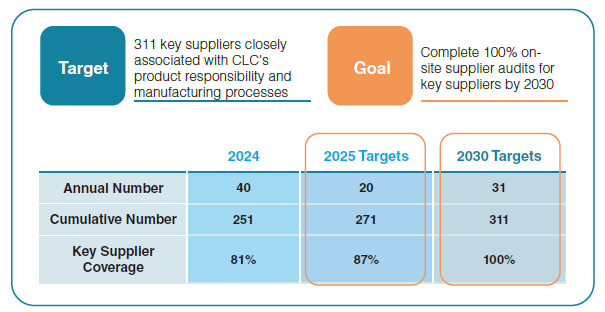

Key On-site Supplier Audit Target: 100% by 2030

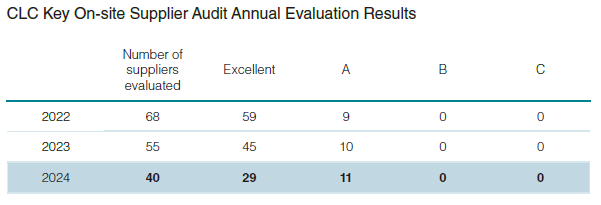

CLC conducts annual supplier evaluations under ISO procurement procedures. Cross-department teams assess key suppliers and classify results into four grades: Excellent, A, B, and C. Management strategies are implemented according to these results.

Since 2020, CLC has implemented an on-site audit system for key suppliers and established an annual target to expand evaluation coverage by 10%, with a goal of achieving 100% coverage by 2030.

As of 2024, CLC completed on-site audits for 251 suppliers, achieving 81% of the 2030 target, with 40 new suppliers evaluated in 2024. The audit result shows that 29 suppliers were rated Excellent and 11 rated A; no suppliers were rated B or C. CLC conducts annual on-site audits, continuously refines assessment criteria, and assigns staff or experts to support lower-rated suppliers in improving sustainability management.

CLC Initiated Tier 1 Supplier Climate Questionnaire to Enhance Supply Chain Carbon Data Management

Establish a supply chain carbon database to accelerate low-carbon transition

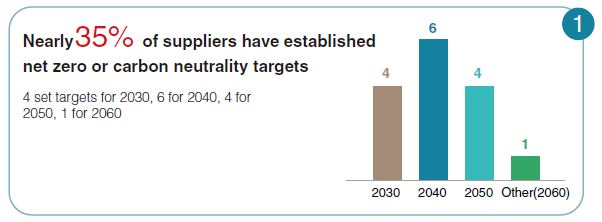

CLC established the Carbon Neutrality Alliance in 2023, targeting valid carbon data collection from over 70% of key Tier 1 suppliers by 2030. CLC developed an industry carbon database, trained digital low-carbon professionals, and launched a supply chain climate questionnaire survey in 2024.

The survey was conducted from November 15, 2024 to January 15, 2025, targeting 44 key Tier 1 suppliers in the raw materials and processing categories. The assessment covered organizational greenhouse gas emissions and product carbon footprint.

The 2024 survey obtained over 30% valid carbon data

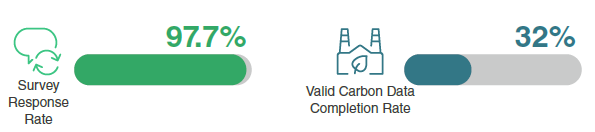

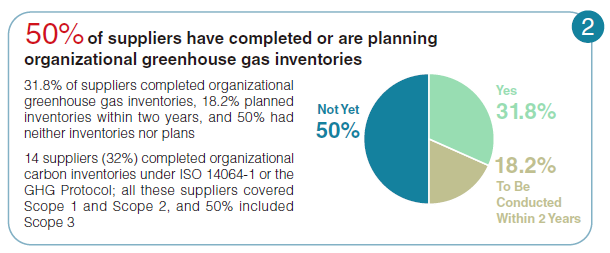

The survey achieved a 97.7% response rate (43 suppliers), with 14 suppliers (32%) having completed organizational carbon inventories. In the 1st year,CLC obtained valid carbon data from over 30% of suppliers.

Survey Findings and Next Steps

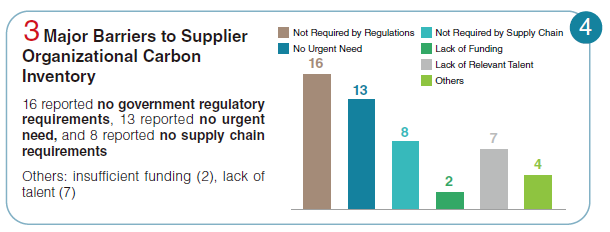

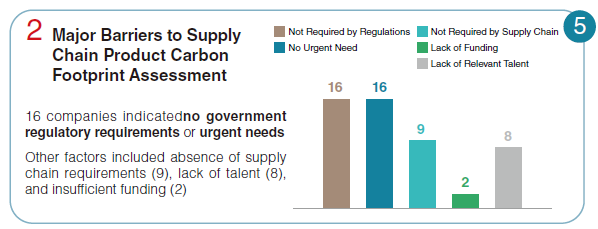

The 2024 CLC Tier-1 Supply Chain Climate Survey found that suppliers had not initiated greenhouse gas or product carbon inventories due to lack of regulatory requirements, urgent need, or supply chain requests. These findings highlight the critical role of government policy and supply chain expectations in driving supplier engagement in carbon management.

CLC will accelerate low-carbon supply chain transformation through five action guidelines, working with supply chain partners to build a resilient low-carbon industrial ecosystem and advance sustainable value co-creation.

Enhancing Supply Chain Sustainability through Supplier Training

In 2024, CLC held 6 supplier training sessions with 115 suppliers, focusing on low-carbon transition and environmental management. CLC delivered a keynote speech at Da Fon Environmental Technology, sharing ESG implementation experience with senior management and addressing strategies for low-carbon transition and green production under global carbon neutrality trends. CLC will continue to strengthen supply chain collaboration to advance environmental sustainability and occupational safety management.

.jpg)

Enhancing supply chain resilience through local sourcing, with local suppliers accounting for 85.7%

CLC prioritized Taiwanese suppliers and set a 2030 target for local procurement to exceed 75% of total value. In 2024, local suppliers accounted for 85.7%, up 2.8% YoY; local procurement value was 68.0%, down 1.7% YoY due to increased overseas purchases of high-end equipment supporting the equipment upgrade transformation strategy. CLC annually adjusted its local procurement strategy and will continue to strengthen supply chain resilience and pursue its targets.