Sustainable Products and Development

● Strategy: Adhering to the 3R principles—Reduce, Reuse, Recycling—to achieve full resource recycling, advance R&D of diverse low-carbon products and services, and generate sustainable value from each sheet of paper.

● Goals of 2030:

◆ Recovered paper utilization rate for industrial paper: > 97% in Taiwan; > 94% in Vietnam

◆ Invest continuously in innovation and R&D to advance sustainable solutions

◆Innovate diverse low-carbon household paper products to expand sustainable consumption value

Sustainable Products and Development

In 2024, the Group reused 2.35 million tonnes of recovered paper, preserving 47 million treesPaper products are primarily made from recovered paper and sustainable forest fibers. After use, paper can be recycled or naturally decomposed, minimizing environmental impact. Circular properties enable broad application across industries. As demand for sustainability increases, paper is the preferred material for packaging and transport.

As a leading paper manufacturer, CLC is committed to developing a circular economy sustainable business model focused on environmentally friendly products and services. CLC continues to enhance processes, adopt advanced environmental equipment, and implement intelligent production and sales systems to increase the use of recovered paper, improve product quality, and achieve carbon reduction. In 2024, CLC's Taiwan Parent Company utilized 1.66 million tonnes of recovered paper (+1.9% YoY, 32,000 tonnes). The recovered paper utilization rate rose by 0.2% to 95.1%. For industrial paper, the utilization rate also increased by 0.2% to 97.7%. All paper types and industrial paper met established goals. In 2024, Vietnam Binh Duong Paper Mill utilized 690,000 tonnes of recovered paper (+16% YoY, 100,000 tonnes), raising the recovered paper utilization rate for industrial paper to 95.1%. Groupwide, CLC utilized 2.35 million tonnes of recovered paper in 2024, generating resource circulation benefits and indirectly preserving 47 million trees, contributing to secondary forest creation.

*Note: Using 1 tonne of recovered paper pulp reduces the need to cut down 20 trees.

Less is More!

CLC Diverse Low-carbon Products: Maximizing Value with Minimal Resources

Global demand for paper packaging has grown steadily due to the plastic-reduced trend and the development of emerging economies. Increased consumer focus on sustainability has raised the penetration rate of eco household paper made from 100% recovered paper. During the pandemic, demand for household cleaning products increased due to greater attention to hygiene.

CLC applies the "Less is More" principle to maximize product value with minimal resources, continuously developing diverse low-carbon products to meet global demand for sustainable packaging and daily necessities, contributing to a net-zero future.

Seizing the Low-carbon Packaging Revolution, Creating Green Warehousing Solutions

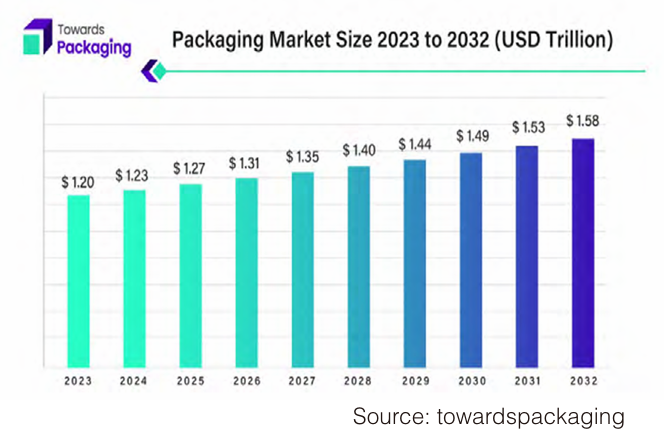

Driven by the global e-commerce market, the packaging market is projected to grow from USD 1.20 trillion in 2023 to USD 1.58 trillion in 2032, with a compound annual growth rate of 3.1%. In 2021, the Ministry of Environment (Taiwan) reported annual consumption of 220 million sets of single use e-commerce packaging in Taiwan, with demand expected to double by 2030. Over the past decade, the packaging industry has shifted toward digitalization and green innovation. Companies must implement sustainable packaging strategies to reduce environmental impact and meet market demand.

Adhering to the 3R principles—Reduce, Reuse, Recycling— CLC develops low-carbon, plastic-free, and lightweight multifunctional packaging products based on the product lifecycle to promote green consumption and waste reduction. Through technologies, CLC reduces product carbon footprint, ensures packaging protection, and improves logistics efficiency to maximize carbon reduction. In 2023, CLC completed the 1st product carbon footprint inventory for industrial paper, establishing CLC low-carbon industrial paper as the preferred choice for global leading brands under international carbon reduction trends.

To reduce e-commerce packaging waste at the source, the company collaborates with e-commerce clients to increase recovered paper utilization, optimize structural and package structure design for lightweight and single-material packaging, adopt water-based inks, reduce printing colors and areas, and develop tape-free packaging. CLC implements the Design-in 3D platform and AI sales forecasting system to use data for precise market and customer demand analysis, further reducing product carbon footprint.

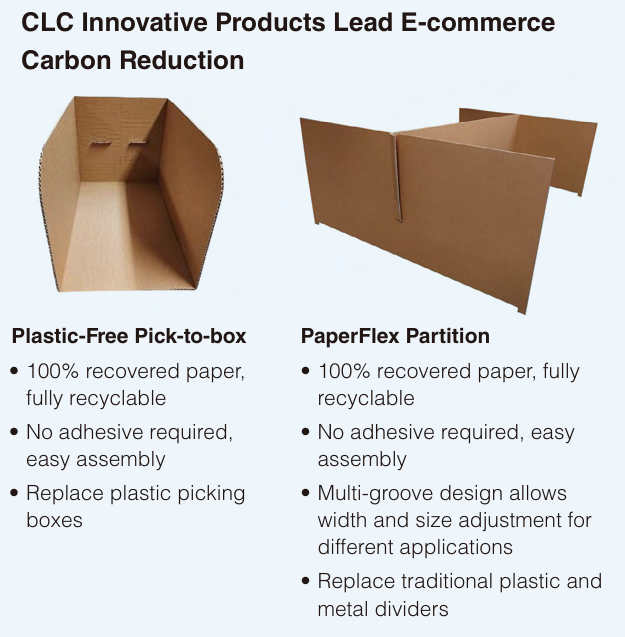

In addition, CLC has developed 100% paper-based shelf dividers and picking boxes for large e-commerce warehouses, enabling rapid assembly and flexible size adjustment. These products have been adopted by international e-commerce brands, reducing resource consumption and plastic use in warehouse management, supporting supply chain carbon reduction, and advancing green warehousing.

Nature-based Solutions: Eco Weed Control Paper Recerti ed for Organic Agricultural Material Certi cation

CLC aligned with the 65th anniversary goals of "Nature Sustainability, Paper towards Net Zero" and supported the United Nations Global Plastics Treaty draft by launching eco weed control paper made from 100% locally recovered paper in 2023,and obtained the Ministry of Agriculture's organic agricultural material certification for 2 consecutive years (2023~2024).

CLC eco weed control paper replaces plastic mulch films, reduces pesticide residue in soil, and improves farmland permeability and moisture retention. Field tests showed a 23-fold reduction in weed growth, significantly decreasing manual weeding in organic rice cultivation. This enhanced agricultural resilience to climate change and ensured sustainability and food security.

CLC will continue R&D Innovation to deliver Nature Sustainability solutions with each sheet of paper and expand application of these products to fruit trees, vegetables, flowers, and specialty crops to drive sustainable agricultural transformation.

R&D Innovation: Diversi ed Sustainable Products and Services

CLC invests over NTD 100 million annually in R&D, focusing on green and niche product development, process improvement, and digitalization to enhance production efficiency and reduce carbon emissions, addressing global trends and demand for sustainable paper materials.

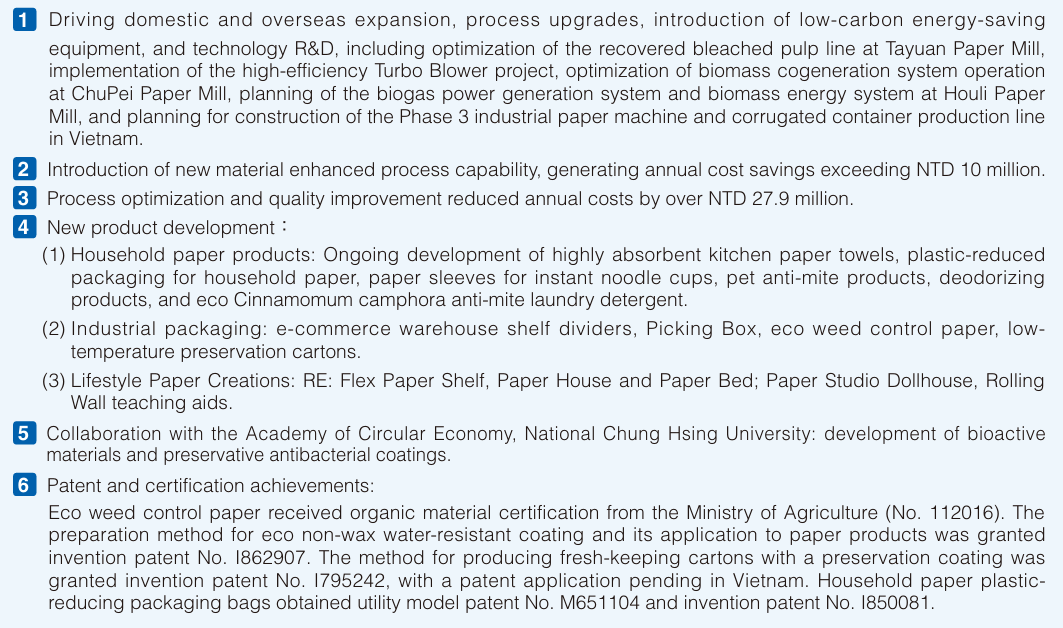

In 2024, CLC's R&D expenses, excluding capital expenditures and equipment costs, totaled NTD 128 million, with the following outcomes:

CLC Household Products:

Pamper Your Loved Ones with Love and Tenderness

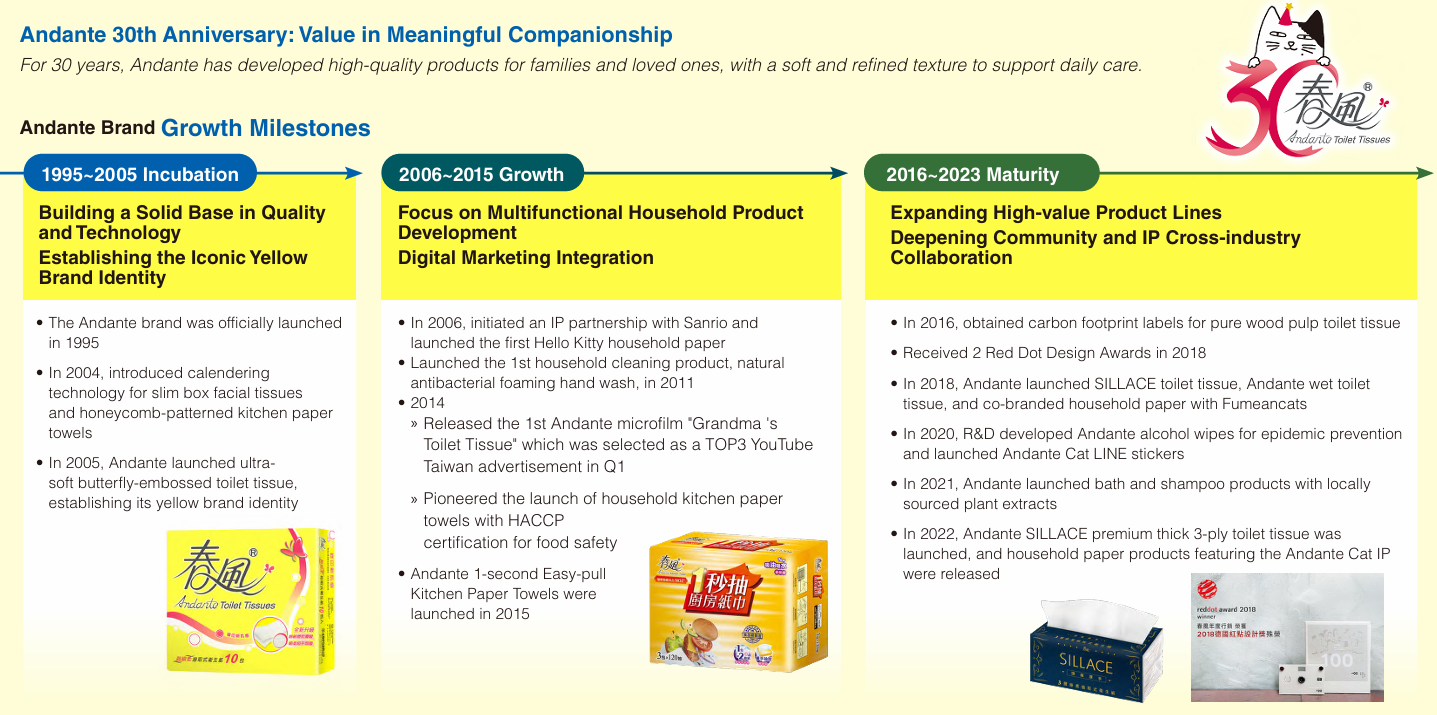

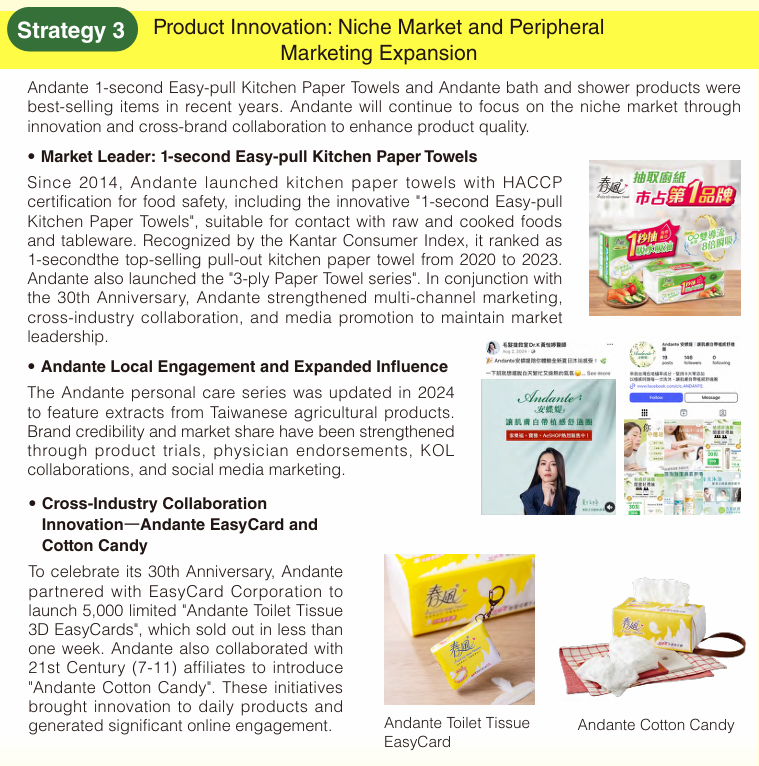

CLC entered the Taiwan household paper market in 1993 and launched the Andante brand in 1995. Following the 2004 acquisition of Baolong paper mill, CLC introduced the Lover, Dandelion, and Snow Soft brands, establishing a comprehensive product line covering toilet tissue, facial tissue, kitchen towels, and hand towels. ChuPei Paper Mill implemented Taiwan's first automated household paper warehouse, Asia's first million-tonne wind power system, and Taiwan's largest high-efficiency biomass cogeneration system. By integrating R&D center resources and academic collaboration, CLC developed high-value extraction and low-carbon diversified products to meet various needs.

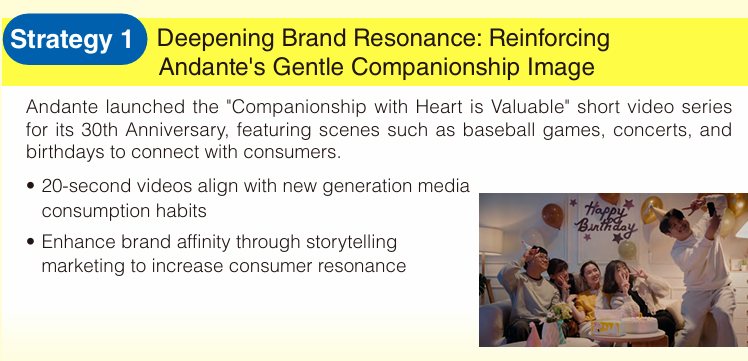

In 2024, CLC launched the Dandelion Eco Convenient Pack Toilet Tissue and the Locally Extracter Personal Care Series by Andante to advance low-carbon, plastic-reduced, and nature-based solutions. In 2025, for the 30th anniversary of the Andante brand, CLC will introduce box facial tissues made entirely of paper without lamination. These initiatives promote daily sustainable practices and reinforce CLC's long-term commitment to sustainability.

Sustainable Regeneration, Enabling the Virtuous Cycle

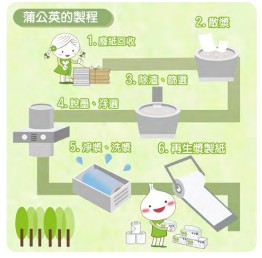

❙ Dandelion Eco Household Products—Comprehensive Implementation of Green Principles from Materials to Manufacturing

Toilet tissue is the most widely used single-use product in Taiwan, with high resource consumption and no recyclability. To advance the circular economy and responsible consumption, CLC uses FSC™-certified pulp for household paper and has invested in producing eco toilet tissue from recovered paper, a process more complex than using virgin pulp. In 2009, CLC launched the Dandelion series made from 100% recovered paper with quality comparable to virgin pulp, and uniquely adopted wind power in production. This achieved environmental sustainability across material sourcing, manufacturing, and finished products, integrating toilet tissue into the circular economy.

Dandelion Eco Multipurpose Bag achieved cumulative sales of 1,200,000 bundles, reducing plastic by 42,000 kg

*Note: According to the New Taipei City Environmental Protection Bureau, reducing the use of one New Taipei designated garbage bag achieves a Carbon Reduction of 0.075 kgCO2e.

CLC expanded its environmental initiatives beyond household paper by launching Dandelion eco household detergents in 2022 and upgrading to 100% recycled plastic bottles in 2023. In 2025, CLC plans to apply for the Green Mark for Dandelion laundry capsules to increase sustainable product options.

Dandelion Eco-Household Official Website

Dandelion Facebook

.jpg)

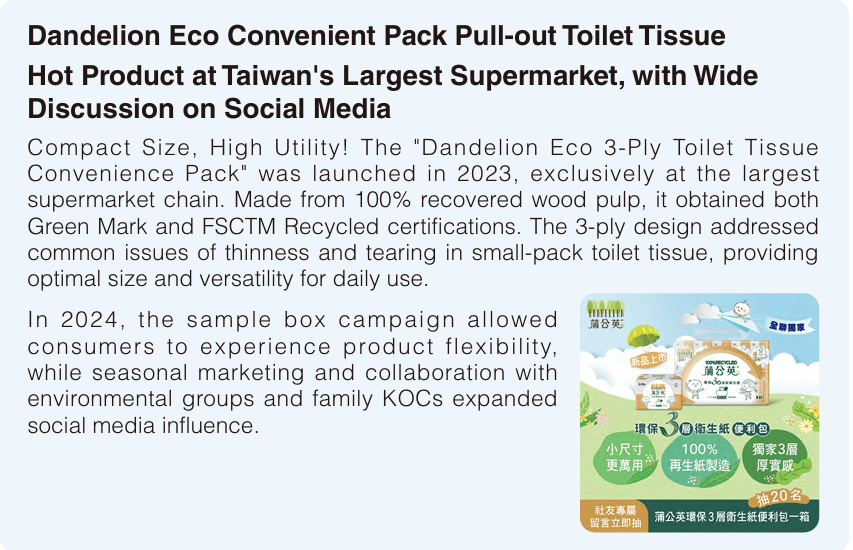

❙ Exclusive Eco Household Paper Products Launched in Key Channels to Promote Recovered Toilet Tissue

To expand the eco household paper market and support the Green Lifestyle policy, Dandelion launched convenient pack eco toilet tissue exclusively at PX Mart in 2023 and developed a 3-ply large pack with 20% more sheets for Carrefour to increase green product accessibility. In 2024, updated carbon footprint packaging was introduced to strengthen communication on CLC's sustainability initiatives. That year, Dandelion series sales exceeded 38 million packs, with annual growth of 10.83% and steadily increasing market penetration.

❙ Diversi ed Brand Marketing Raises Circular Resource Utilization Awareness

Dandelion advanced green consumption and sustainability awareness through integrated online and offline marketing. For Earth Day 2024, the brand launched a campaign utilizing press releases, KOC collaborations, and social media to increase exposure of keywords such as 'eco toilet tissue' and 'recovered paper pulp,' achieving 7 million impressions and reaching 2 million people.

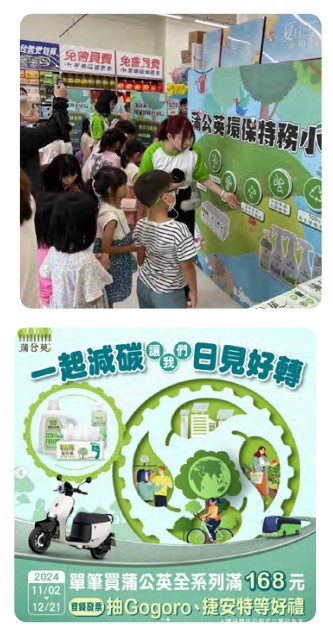

To strengthen face-to-face engagement with consumers, the company partnered with Carrefour stores to hold the Dandelion Environmental Agent Academy, providing interactive experiences to promote green consumption and sustainability among children. In addition, Dandelion and Michelin selected restaurants launched the "Let's Reduce Carbon for a Better Tomorrow" initiative to promote sustainable dining, supported by an invoice registration campaign to advance the Green Lifestyle—Green Dining approach.

Furthermore, the brand supported the SIMBALION Art Studio, Huisun Wood Culture Festival, and Fayaque 24-Hour Photography Marathon to promote carbon reduction, recycling, and environmental protection, and strengthened consumer recognition of Dandelion's carbon reduction and sustainability through brand engagement.

❙ Circular Economy Innovation – Recycling in Practice

"Advancing the Virtuous Cycle, CLC leverages industry innovation to drive company-led green transformation, connecting government, the papermaking industry, business partners, and consumers through initiatives such as document destruction services and food paper container recycling."

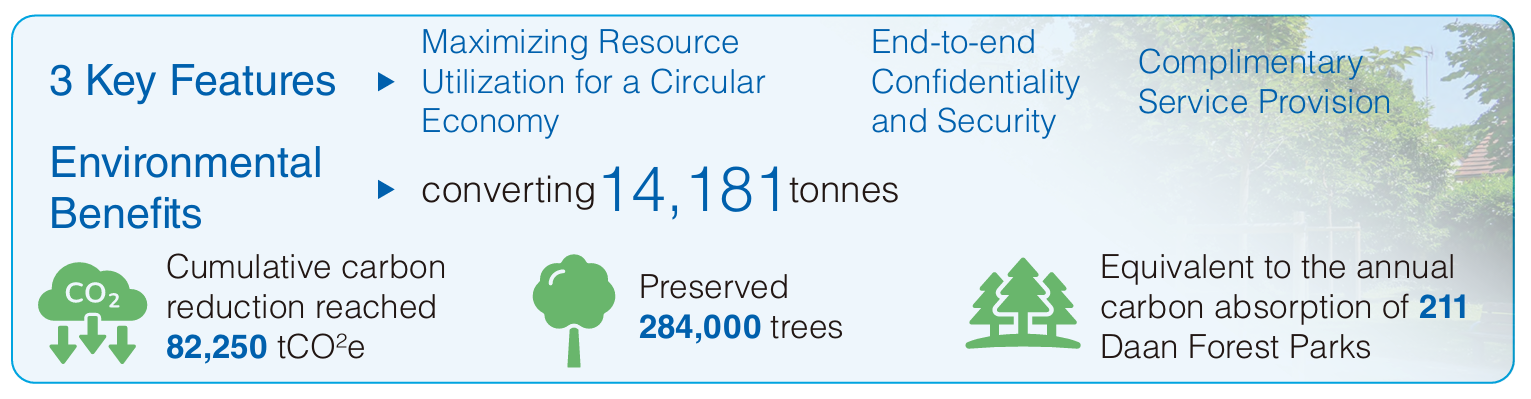

❙ CLC's Document Destruction Technologies Enabled Recycling, Accumulating a Cumulative Carbon Reduction of 82,250 tCO2e and Preserving 284,000 Trees

Since 2013, CLC has utilized existing pulp dispersion equipment to provide free confidential document destruction services. Over 12 years, CLC assisted nearly 400 partners—including government agencies, listed companies, financial and insurance firms, and defense units—by converting 14,181 tonnes of confidential documents into over 61.26 million packs of eco toilet tissue, demonstrating both environmental and economic benefits.

*For more details: https://reurl.cc/o80MLQ

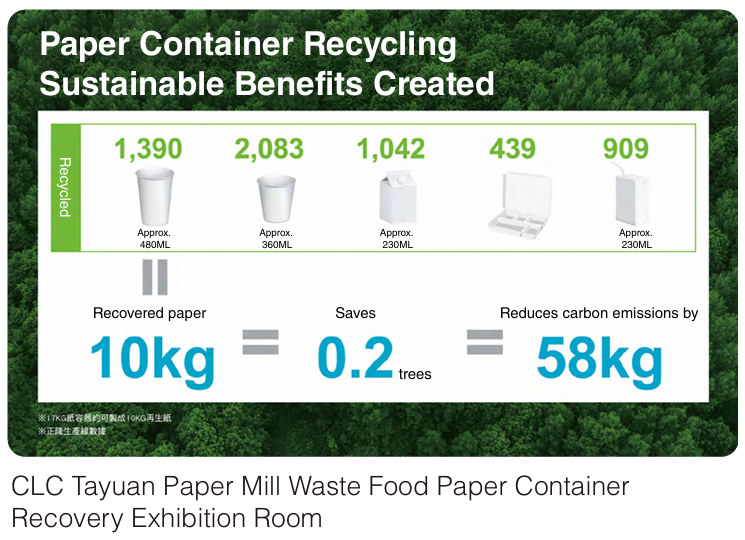

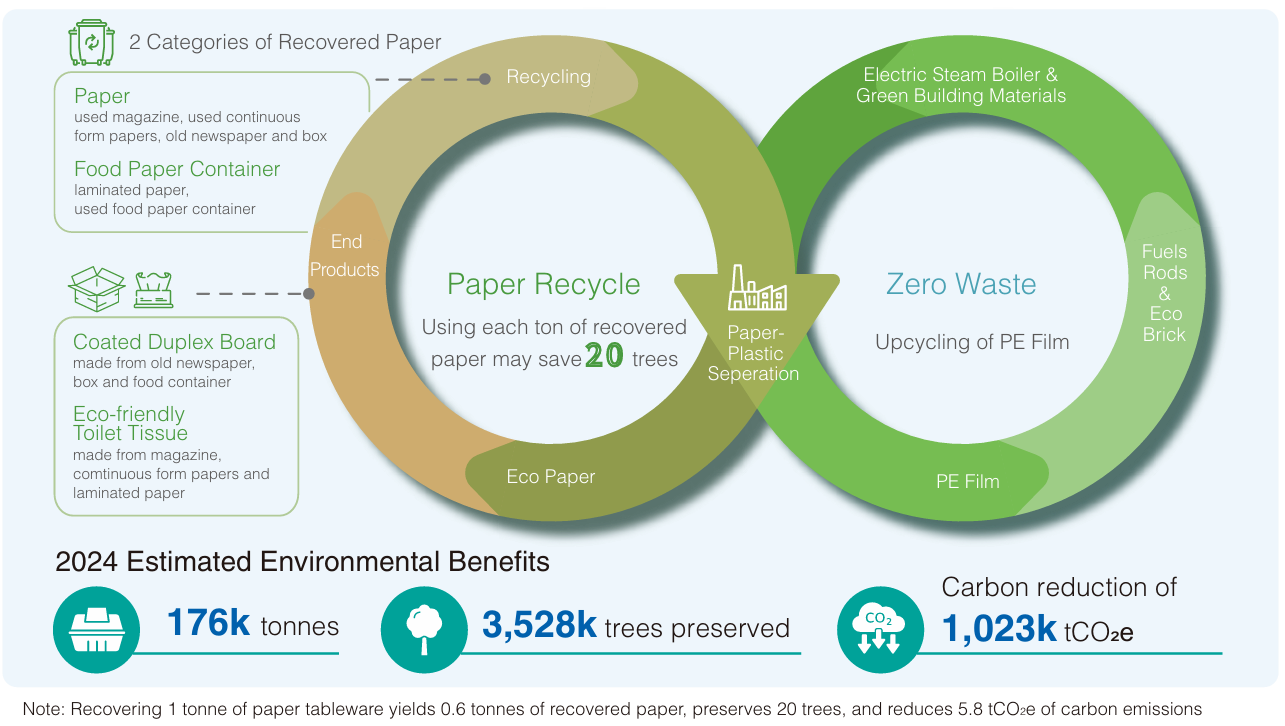

❙ Total Recycling Food Paper Containers: Dual Circulation Drives Low-carbon, Plastic Reduction, and Green Business Development

Annual food delivery and takeout in Taiwan generated over 8 billion waste food paper containers. The Ministry of Environment (Taiwan) designated food paper containers as mandatory recycling items, requiring processing plants to separate plastic lining from paper pulp for recycling and reuse. Due to limited public awareness, many consumers disposed of these containers as general waste or mixed them with regular waste paper, resulting in low recovery rate and increased processing costs for paper mills.

❙ CLC Leads Global Waste Food Paper Container Processing Volume

Since 2018, CLC established the 1st food paper containers total recycling line at the ChuPei Paper Mill. In the same year, CLC launched the Recycling Supply Chain Transformation and Upgrade project, supporting 167 recycled paper suppliers in upgrading operations, achieving source separation, and reducing recovered paper residual waste by nearly 40% compared to 2017. CLC also established a dedicated recycling system for paper lunch boxes. By 2025, the number of waste food paper container recyclers reached 56, a 56-fold increase from 2018. Separated impurities and plastic lining are converted into green energy fuel and eco building materials, supporting a sustainable business model.

CLC advanced waste food Paper container recovery by installing a 66,000 tonnes recovered bleached pulp line at Tayuan Paper Mill in 2023. By the end of 2024, ChuPei Paper Mill's certified processing volume for food paper containers was approved by the government, increasing by 50% to 3,000 tonnes per month. The group's total certified annual processing volume for waste food paper containers reached 176,000 tonnes, enabling the recovery of over 50% of Taiwan's waste food paper container resources and achieving a carbon reduction of 1.02 million tonnes. CLC engaged associations, schools, government agencies, and enterprises through diverse collaborations to expand carbon reduction impact and opened its factories for public visits to raise awareness of sustainability responsibilities.

Secondary Forests Drive Circular Economy: Waste Food Paper Containers Transformed into Low-carbon Products

Through the product lifecycle—material use, product design, green production, logistics, and end-user consumption—the process of recycled resources, papermaking, and packaging generates circular economy value.

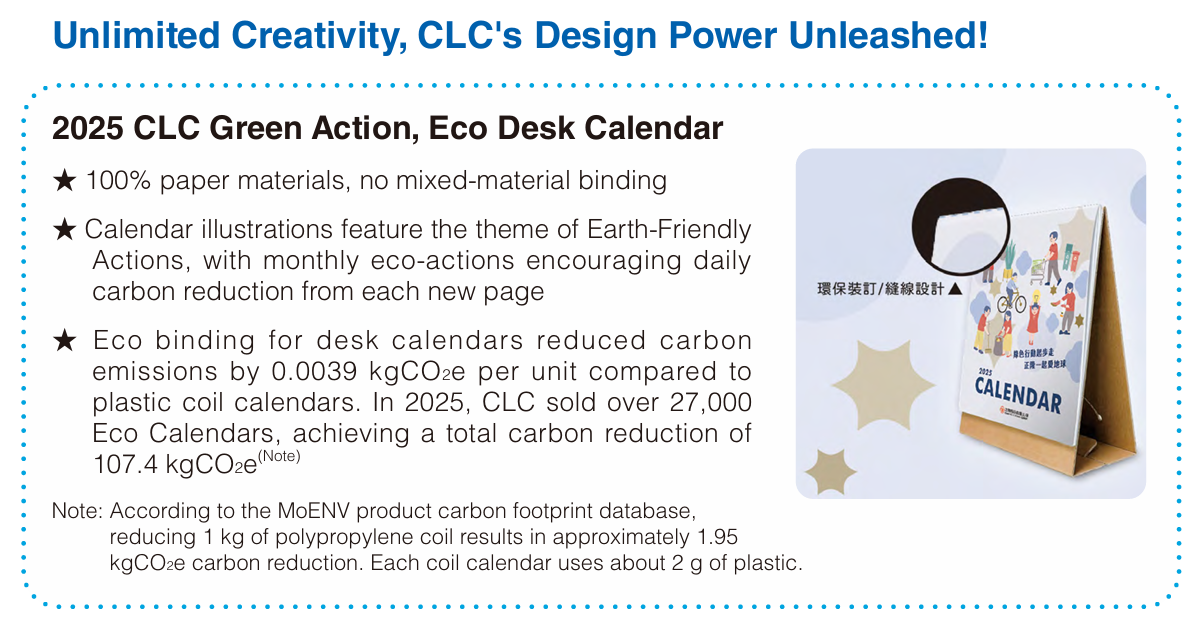

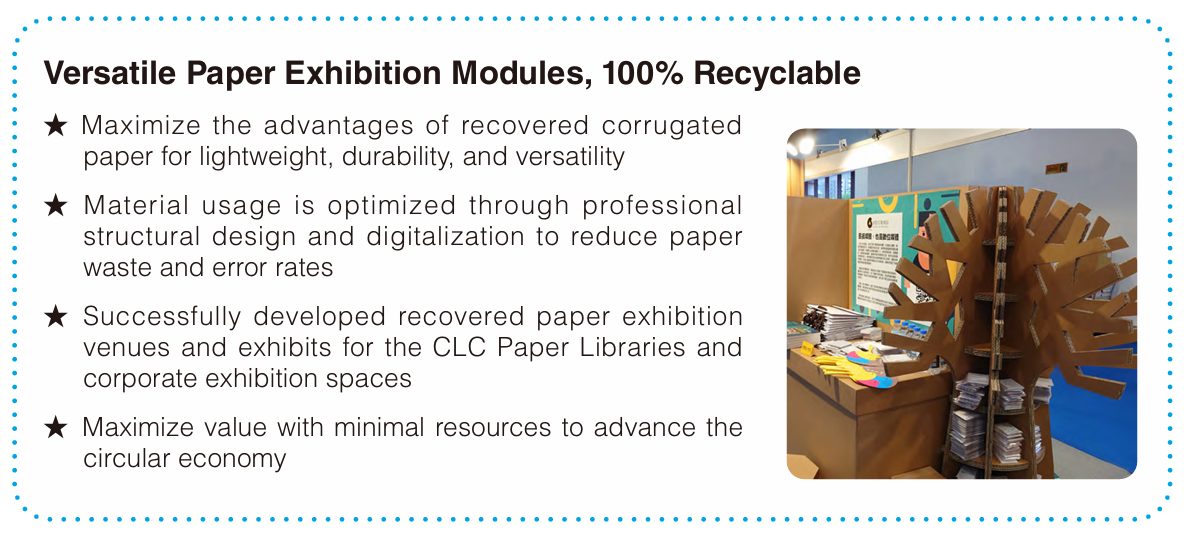

❙ Cultural Creativity Goes Green: From Playful Design to Sustainable Living

Paper studio Play the eco way

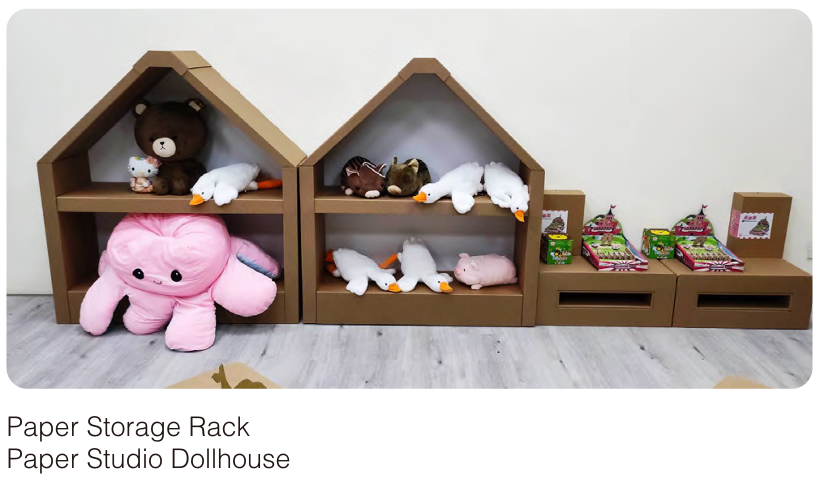

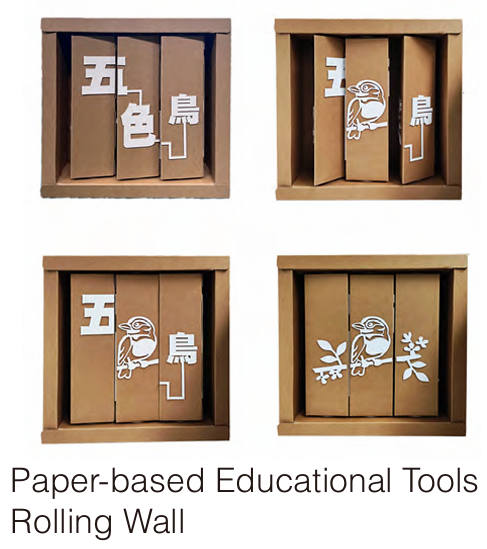

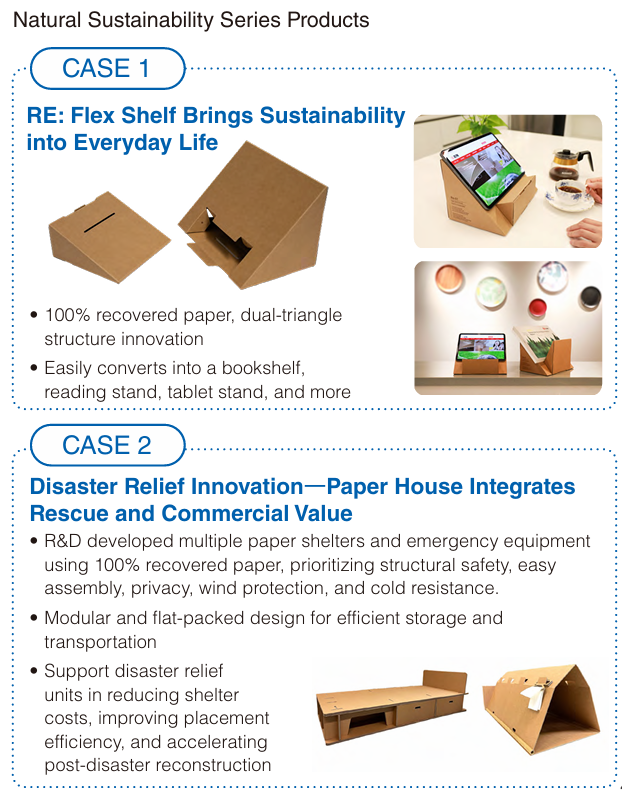

Since 2013, CLC has launched the Paper Studio brand, developing children's furniture and cat toys made from 100% recovered paper. In 2024, Paper Studio introduced fully paper-based chairs, the Paper Studio Dollhouse, and the Paper Studio Rolling Wall as low-carbon innovation products. The Dollhouse serves as both toy storage and bookshelf, and its all-paper design enables complete recycling and reuse when no longer needed. The Rolling Wall provides cognitive learning functions, allowing children to recognize images and text by flipping panels.

Paper Studio collaborated with the Uni-President Good Neighbor Cultural and Educational Foundation to launch the Good Neighbor Christmas Book House, featuring a paper library and MINI Paper Studio products, including Little Desk, Paper Tree Chair, Display Bookshelf, Little Elephant, and Dandelion Little Pu and LittleYing dolls, to promote awareness of recovered paper's potential among children through interactive play.

Driving ESG Innovation and Value Creation"Innovation and R&D drive CLC's growth. CLC focuses on advanced industry technologies, strengthens R&D capabilities, and implements proposal-based improvements and Excellent Proposals to promote benchmarking, supporting ESG development."

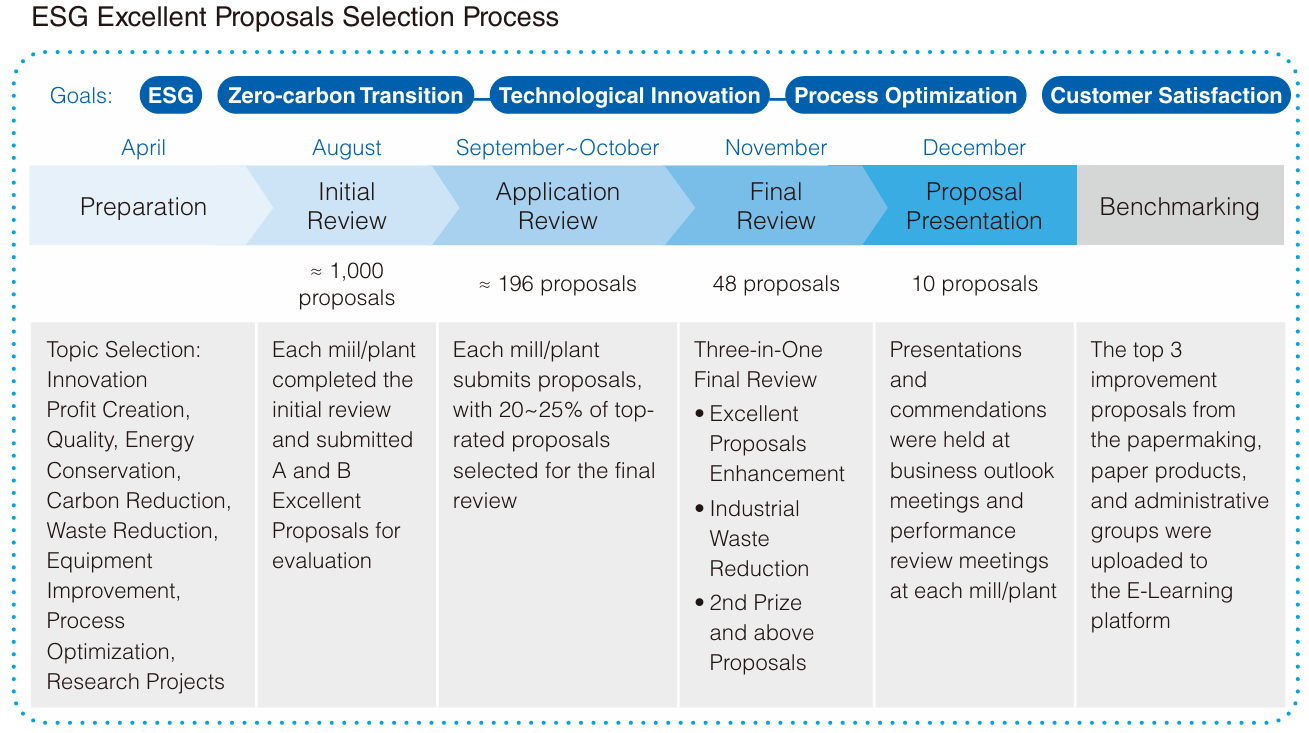

❙ Excellent Proposals Mechanism, Employees are encouraged to identify issues and collaboratively develop ESG innovation initiativesSince 1980, CLC has implemented proposal-based improvements, QCC and TPM. In 2008, CLC launched Excellent Proposals Improvement and Management Mechanisms, integrating evaluation and reward systems to advance process optimization, technology development, green energy innovation, and customer service, enabling carbon reduction suggestions to reach top management. In response to ESG transformation, CLC adopted competition-based incentives to drive employee problem identification and innovation. Since 2021, CLC has extended ESG Excellent Proposals Mechanism to overseas sites, promoting ongoing innovation and optimization across the group.

Over 1,000 proposals generated nearly NTD 170 million in profit in 2024, Generated NTD 1.2 billion profit over the past 4 years

In 2024, over 1,000 proposals were submitted, with 48 Excellent Proposals shortlisted for the finals: 10 from Administration, 18 from Papermaking, and 20 from Paper Products. The expected profit was nearly NTD 170 million, with measurable improvements in production efficiency, sales quality, carbon reduction, service innovation, and work efficiency.

❙ Public Presentation of Outstanding Proposal to Foster Benchmarking and Knowledge Sharing

Outstanding cases selected annually were presented, recognized, and awarded bonuses at mill/plant's business outlook meetings and company-wide performance review meetings. Case content was published on the CLC E-Learning platform and in internal publications to promote knowledge sharing and establish a benchmarking culture.

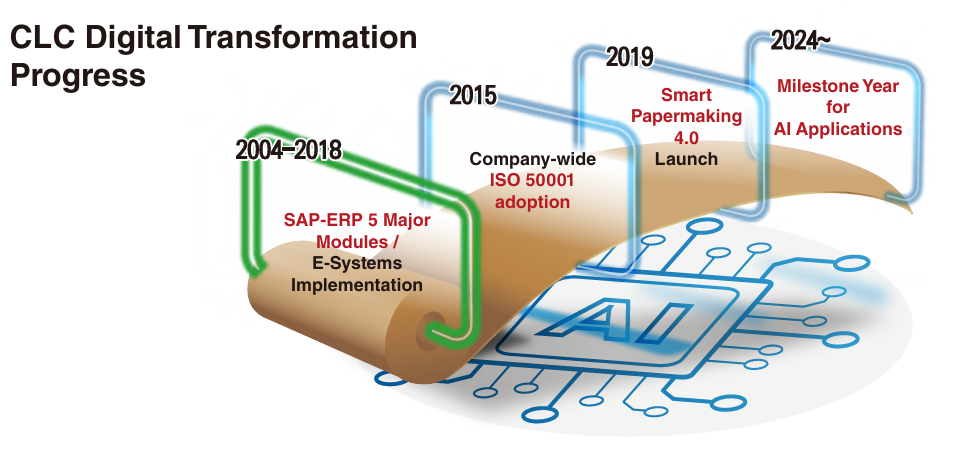

❙ AI Pioneer in the Paper Industry Pioneering Digitalization and Intelligent Management to Accelerate Low-carbon Transition

Amid global market shifts, CLC advanced digital and intelligent transformation to enhance competitiveness. In 2004, CLC completed group-wide ERP implementation. From 2012 to 2017, CLC developed the cogeneration energy digital system at Houli Paper Mill, a digital procurement platform, and a household paper CRM system. In 2019, CLC launched the "smart papermaking 4.0" project, integrating equipment, implementing energy-saving and carbon reduction monitoring, and automating management to improve production efficiency and reduce labor dependence. CLC became the 1st in the papermaking industry in Taiwan to implement intelligent production and sales, accelerating the transition to low-carbon operations.

2024 Milestone Year for AI Applications: Launch of Intelligent Upgrades

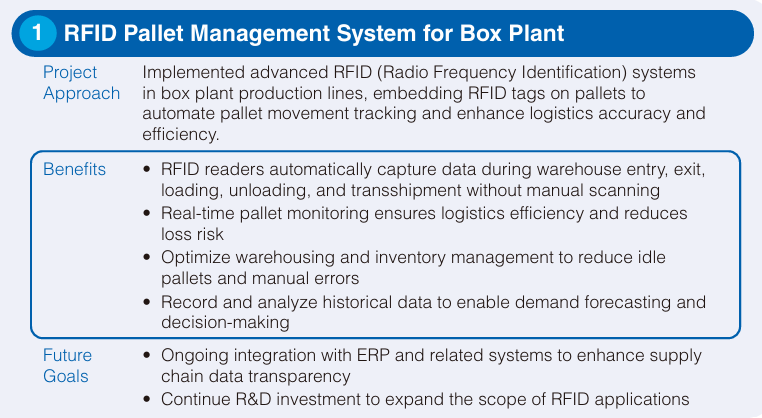

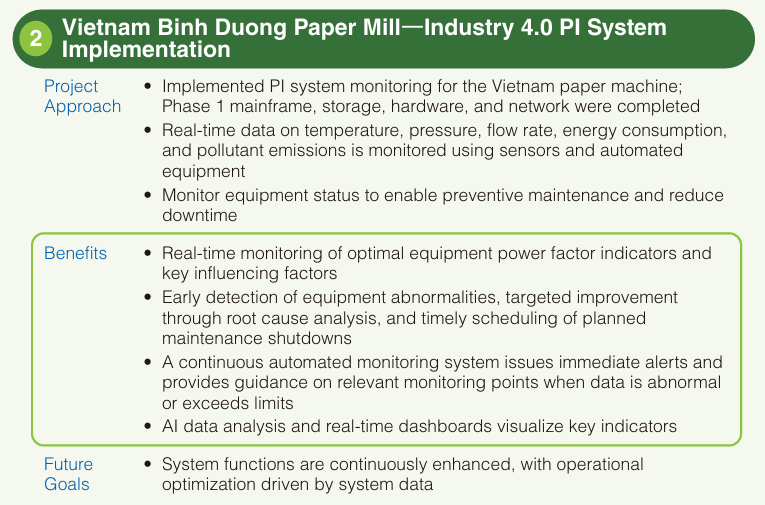

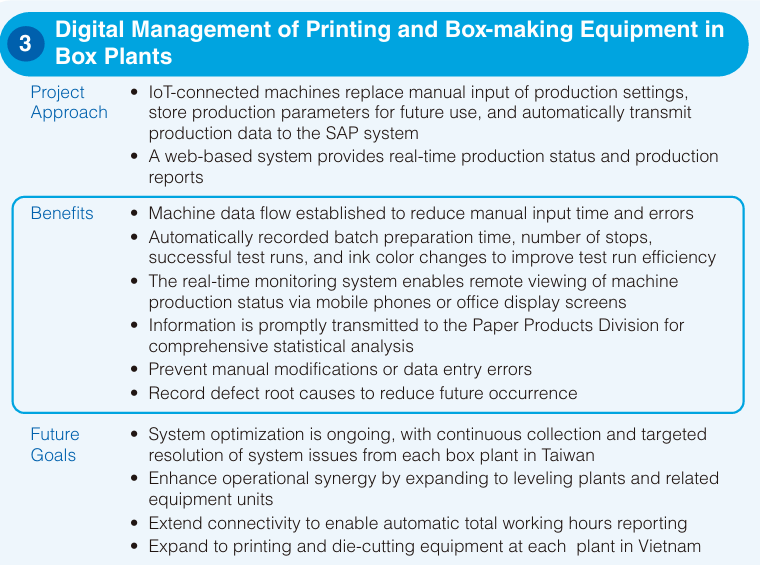

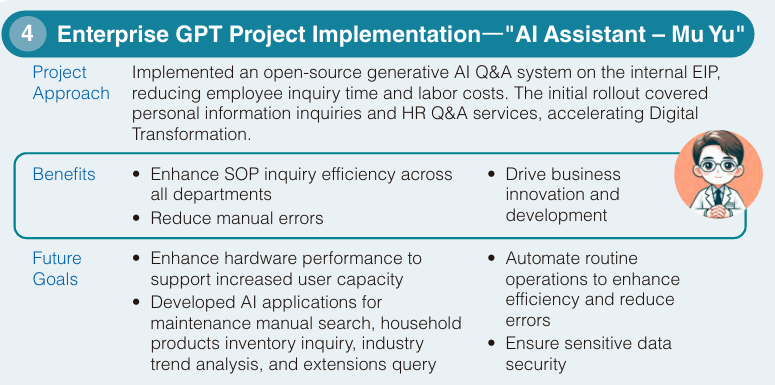

In response to rapid AI development, CLC designated 2024 as the Milestone Year of AI applications, building on a foundation of automation, digitalization, and intelligent data. In 2024, CLC implemented 4 AI projects: an in-house GPT system to enhance administrative and HR efficiency, RFID pallet management at box plants, digital management of printing and box-making equipment at Taiwan box plants, and PI system planning at Binh Duong Paper Mill in Vietnam. Since 2019, CLC has completed 29 AI projects under smart papermaking 4.0, advancing process digitalization and intelligent optimization. CLC continues to expand smart papermaking 4.0 to include AI smart manufacturing for the Vietnam Binh Duong paper machine and cogeneration system to improve energy efficiency and carbon reduction. We keep integrating digital inspection systems across all mills/plants to achieve seamless online smart manufacturing and offline digital inspection. Real-time data collection and analysis are optimizing production processes, increasing equipment efficiency, strengthening quality management, and reducing energy consumption. CLC continues to upgrade the ISO 27001 information security management system (ISMS) to enhance information security for industrial control systems.

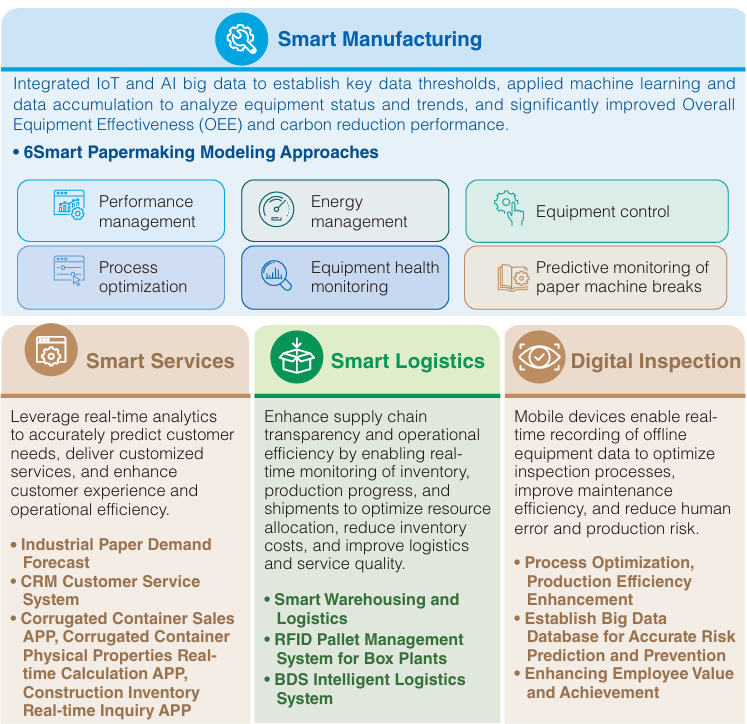

❙ CLC Smart Papermaking 4.0: Smart Manufacturing Drives Low carbon Transformation

CLC Smart Papermaking 4.0 centers on Smart Manufacturing to enhance production efficiency and energy management, achieving low-carbon and green production. By applying AI, big data, cloud computing, IoT, and 5G, CLC strengthens knowledge transfer and early warning management, optimizes processes, and increases operational efficiency, delivering both service upgrades and carbon reduction.

CLC is advancing Smart Manufacturing to improve equipment performance and enable energy saving and carbon reduction monitoring, integrating manufacturing, management, and sales systems. To address labor structure challenges, CLC is implementing digital inspection and automated management technologies to reduce labor dependence and strengthen "intelligent manufacturing".

CLC implemented the Power BI interactive business intelligence visualization system to enhance decision-making efficiency and accuracy. In 2024, CLC partnered with the Industrial Development Administration, Ministry of Economic Affairs, to launch the "CLC iPAS Industrial Control Cybersecurity and Smart Manufacturing Supply Chain Program". This program integrated the Information Department, Information Security Center, papermaking, Cogeneration, and environmental units, and collaborated with 10 suppliers to train industrial cybersecurity and smart manufacturing professionals, strengthening industry-wide smart manufacturing and industrial control cybersecurity capabilities to support industry transformation.

❙ "CLC iPAS Supply Chain Program" launched, training 69 green collar smart industrial control professionals

CLC partnered with the Industrial Development Administration, Ministry of Economic Affairs, to launch the "CLC iPAS Smart Manufacturing and Cybersecurity Professional Talent Training Program". The program adopted a three-track approach of lectures, hands-on practice, and certification, focusing on smart machinery and cybersecurity, and aligned with international standards. 10 companies from material, chemical, equipment, and information sectors participated across multiple supply chain stages. The program trained 69 green-collar smart industrial control professionals with practical skills.

2024 Key Initiatives

.jpg)