Action for Climate Change

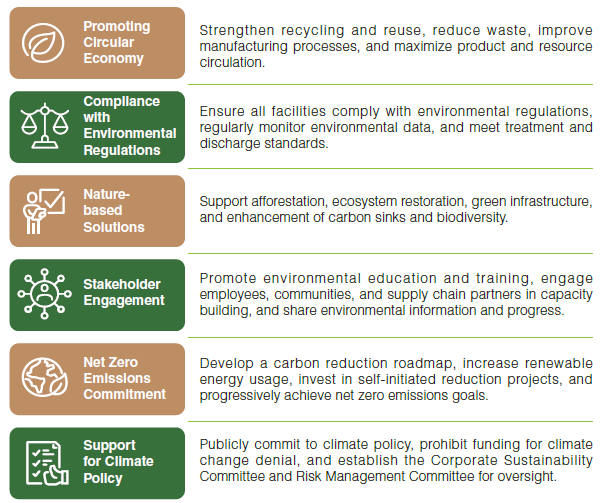

CLC Environmental Sustainability StrategyCLC's sustainability policy centers on smart low-carbon operations, resource circulation, and environmental stewardship, fully integrating sustainability into business operations and management decisions. CLC implements life cycle management from product design and process optimization to resource recovery and reuse, advancing carbon reduction and environmental protection. This policy guides all employees and underpins CLC's net zero transition and climate resilience, strengthening its competitiveness in the global sustainable supply chain.

Policy Promotion and Management Mechanism

CLC's sustainability policy is overseen by the taskforce under the Sustainability Committee and the Risk Management Committee, and is integrated into the ISO management systems of the parent company (including all mills/plants) and its domestic and overseas subsidiaries to ensure comprehensive implementation.

In parallel, stakeholder engagement mechanisms have been established, collaborating with customers, suppliers, communities, and academic institutions to implement projects on environmental education, nature-based solutions, and green innovation, building a sustainable governance network to advance a clean and resilient future through Governance Co-creation.

Environmental Management Verification

We have implemented and applied for certification of international management systems at all mills/plants, including the ISO 14001 environmental management system, ISO 14064-1 GHG inventory, and ISO 50001 energy management system. All operational sites in mainland China and Vietnam have implemented the ISO 14001 Environmental Management System. In 2022, the group's subsidiaries also began greenhouse gas inventories and energy management. Eight sites, including the Binh Duong Paper Mill and Yue Long Plant in Vietnam, and the Chung Hao Plant in Shanghai, China, have received ISO 14064-1 and ISO 50001 certifications.

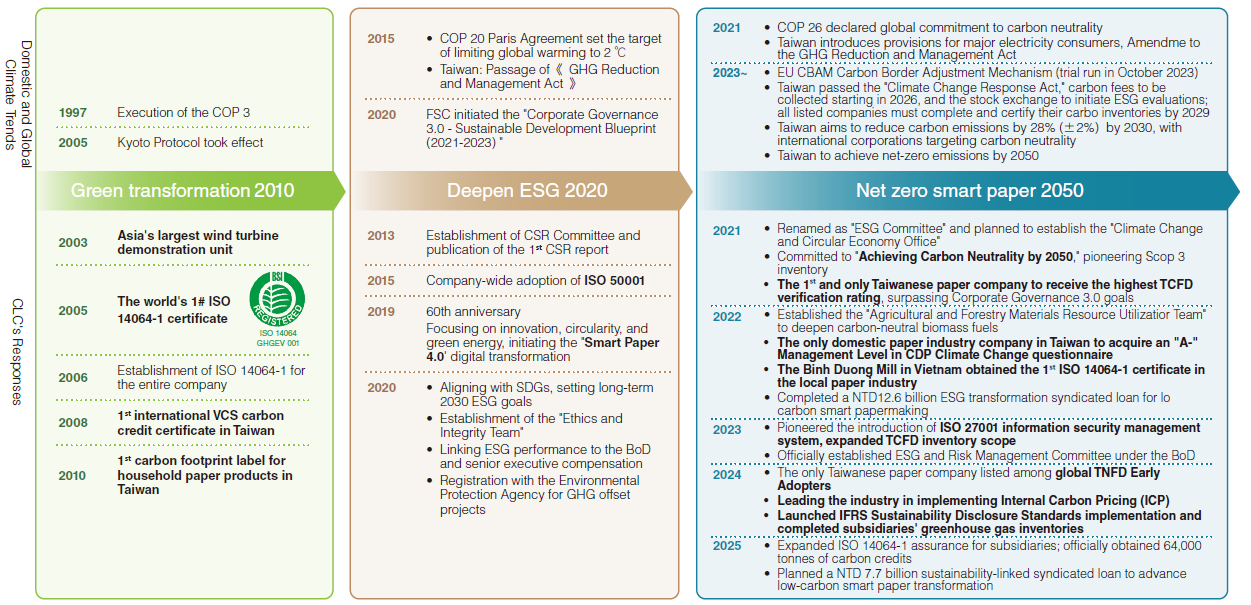

CLC Important Milestones on Climate Governance

Enhancing Climate Risk Governance and Advancing Low carbon Smart Paper Transformation

CLC aligned with international frameworks to mitigate climate change impacts on operations and finances and strengthen organizational climate resilience. In 2021, CLC became the first paper company in Taiwan to pass the TCFD audit and receive the highest rating, establishing a comprehensive climate risk and opportunity identification process and conducting ongoing TCFD reassessments based on major climate policy developments.

In 2024, CLC became one of the first global Early Adopters of the Taskforce on Nature related Financial Disclosures (TNFD), strengthening its focus on nature-related issues. CLC also implemented Internal Carbon Pricing (ICP), launched the IFRS Sustainability Disclosure Standards implementation plan, and completed the greenhouse gas inventory for consolidated subsidiaries.

By 2025, CLC will expand ISO 14064-1 GHG inventory assurance to all consolidated subsidiaries and initiate an NTD 7.7 billion sustainability-linked syndicated loan to accelerate Low-carbon Smart Paper transformation, advancing toward the 2050 carbon neutrality vision.

Advancing International Standards for Climate Resilience and Information Transparency

The circular economy is a practical approach to achieving low-carbon net zero. CLC treats climate change risks as opportunities, focusing on S.M.A.R.T. Low-carbon Intelligent Paper and establishing circular economy sites domestically and internationally. CLC invests in recovered paper recycling, prioritizes Paper-based Solutions (PBS) as Nature-Based Solutions, and advances climate governance to enhance operational resilience.

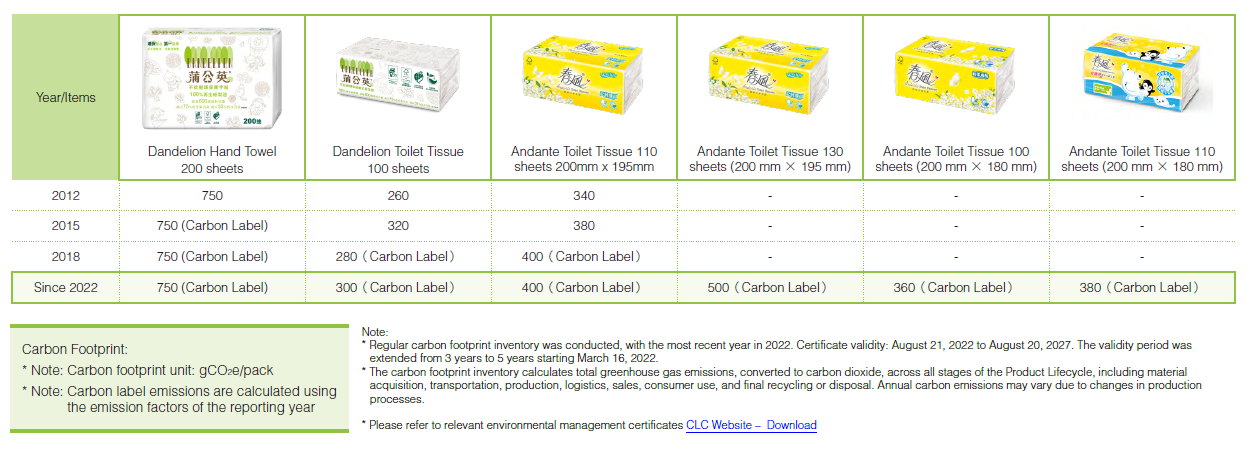

Since 2005, CLC has implemented emission reduction management on production lines after obtaining the world's 1st ISO 14064-1 GHG inventory certificate. In 2008, CLC obtained Taiwan's 1st international VCS carbon credit certificate, and in 2010, Taiwan's 1st carbon footprint label for household paper products. In 2023, CLC formed a Carbon Reduction team with the industry chain and completed Taiwan's 1st product carbon footprint inventory for industrial paper. In 2024, CLC launched a climate questionnaire survey for key Tier 1 domestic and international suppliers to enhance supply chain carbon data management and accelerate zero carbon transition opportunities.

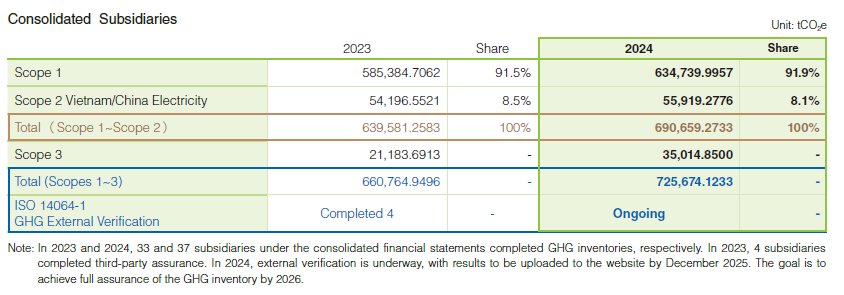

CLC adopted international frameworks to reduce climate-related operational and financial impacts and achieved the Corporate Governance 3.0 goals ahead of schedule. In 2021, CLC became the 1st pulp and paper company in Taiwan to pass the TCFD audit and receive the highest rating. In 2022, CLC initiated greenhouse gas inventories for subsidiaries. Vietnam Binh Duong Paper Mill obtained the 1st ISO 14064-1 GHG inventory certificate in the local pulp and paper industry, with subsequent expansion to other overseas plants. By 2024, all 37 consolidated subsidiaries completed ISO 14064-1 GHG inventories, with key plants completing third-party assurance. CLC will continue to expand third-party assurance for consolidated subsidiaries' greenhouse gas inventories, targeting full completion by 2026.

From Climate to Nature: Shaping Forward-looking Sustainable Low-carbon Strategies

By completing the CDP Climate Change Questionnaire since 2022, CLC has disclosed climate information and enhanced sustainability resilience. In the 2023~2024 Year evaluation, it reached Management Level and, in 2024, was included in the Supplier Engagement Assessment (SEA) A List. The company continues to strengthen carbon management, promote low-carbon development, and implement climate adaptation strategies to accelerate the global sustainability transition. In the same year, CLC became the first TNFD Early Adopters in Taiwan's paper industry. Under the TNFD frameworks, the company assessed the dependence and impact of its business activities on natural resources and, together with industry, government, and academia, launched research projects on nature and biodiversity at its sites, establishing a foundation for localized natural science research.

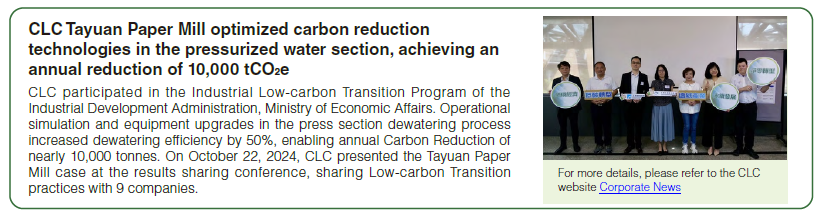

Advancing the Low-carbon Smart Paper transformation, CLC leverages digitalization to expand green production and sales, while integrating product, energy, and water circularity with agricultural and forestry cycles to enhance the regeneration of plant fibers, bioactive materials, and biofuels, thereby establishing the 3R PLUS circular economy blueprint. Digital carbon management has been implemented, with four scientific carbon-reduction pathways defined: improving energy efficiency, developing renewable energy, advancing circular low-carbon fuels, and innovating carbon-negative technologies. CLC participates in national carbon reduction programs, including the Tayuan Paper Mill's involvement in the Industrial Development Administration's Industrial Low-carbon Transition Program. Through academic collaboration, it integrates R&D and cross-industry expertise to research negative emission technologies such as carbon fixation and carbon sequestration, and promotes natural carbon sink development to address climate change.

To ensure the implementation of carbon reduction actions, CLC has adopted a top-down strategy, integrating GHG emission reduction and energy resource efficiency into operational performance indicators. An annual carbon reduction competition encourages innovation proposals and recognizes achievements. In 2024, the Taiwan Parent Company's GHG emissions decreased by 9.38% compared to the base year, achieving short-term goals ahead of schedule.

Climate Risk and Opportunity Governance

Climate governance at CLC is led by the BoD, with the sustainability committee and risk management committee responsible for managing climate-related risks and opportunities. The Climate Change and Circular Economy Office, under the sustainability committee and led by the President, coordinates climate risk mitigation, adaptation, and Low-carbon Transition actions. This office operates within the company's risk management and business unit management systems, executes risk management decisions, and coordinates cross-departmental risk management. Climate-related risks and opportunities are regularly reported to the BoD to ensure a top-down supervisory mechanism.

Aligned with the Paris Agreement target of limiting global temperature rise to 1.5℃ by 2100, CLC has, for three consecutive years, been recognized as a top performer in the CommonWealth Magazine Corporate Carbon Reduction Thermometer. In 2022, CommonWealth Magazine launched the Corporate Carbon Reduction Thermometer Platform (TRIPs), applying international standards and model verification to systematically collect and assess the carbon reduction commitments and results of Taiwanese companies against the 1.5℃ target. In 2024, data from 1,200 companies were collected. The June 2025 report determined CLC's carbon reduction temperature at 1.511℃ , ranking the company among 405 companies with high performance.

Climate Risk and Opportunity Strategy

Through annual third-party verified GHG inventories, CLC assesses Carbon Reduction performance and implements climate change mitigation and adaptation in line with international initiatives.

Focusing on energy management, CLC addresses Scope 1 direct emissions and Scope 2 indirect emissions from electricity use. The company has obtained both wind power and solar photovoltaic renewable energy certificates, implemented AI management, and integrated a digital inspection system to enhance green production efficiency. Notably, CLC was the first paper company in Taiwan to adopt intelligent production and sales.

To accelerate net-zero transformation, CLC has established strategies and response plans for major climate risks and opportunities, ldefining 4scientific carbon-reduction pathways: improving energy efficiency, expanding renewable energy, advancing circular low carbon fuel, and innovating carbon-negative technologies. Through the S.M.A.R.T. Low-carbon Paper Strategy, CLC is building 3R PLUS resource circulation, developing a circular low-carbon biomass material ecosystem, focusing on paper-based Nature Sustainability solutions, and expanding low-carbon product opportunities.

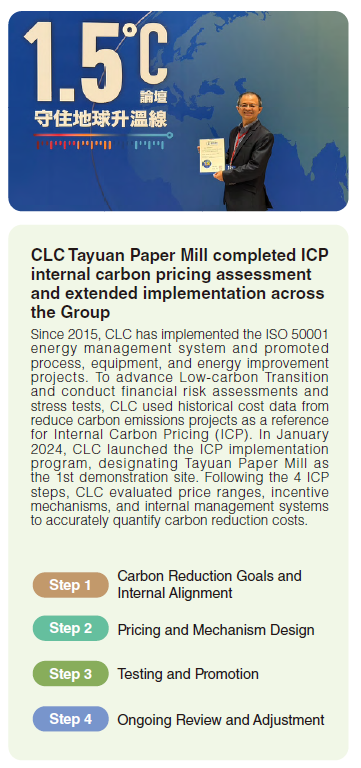

To advance low-carbon transition and conduct financial risk assessments and stress tests, CLC used historical costs from energy saving and carbon reduction projects as the reference for internal carbon pricing. In 2024, Tayuan Paper Mill was designated as the first demonstration site, referencing international carbon pricing trends, global reports, national carbon fee rates, and industry benchmarks to review carbon reduction strategies and systematically assess the overall benefits of its carbon reduction investment portfolio. CLC established a standardized internal carbon pricing assessment framework, extending it to all domestic and overseas sites to evaluate the effectiveness of energy-saving and carbon reduction projects. Each mill or business unit calculates carbon costs in management reports to inform capital investment strategies and major decisions.

In addition, CLC partnered with National Chung Hsing University to establish Asia's 1st Circular Economy Research Institute, advancing circular reuse of agricultural and forestry surplus materials, the 3R PLUS Total-cycle carbon reduction manufacturing chain, and a circular low-carbon biomass resource ecosystem. In 2023, CLC and National Central University conducted a potential assessment and business model study for the Tayuan carbon sequestration pilot site, establishing the nation's 1st Carbon Capture, Utilization, and Storage (CCUS) model for carbon dioxide capture, reuse, and geological storage, supporting progress toward 2050 carbon neutrality goals.

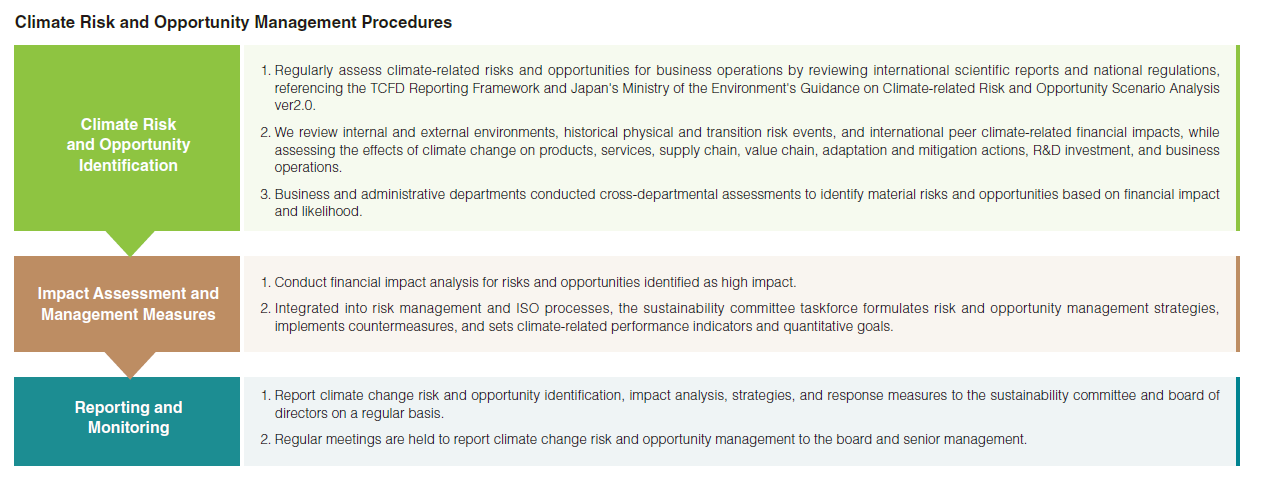

Climate Risk and Opportunity Management

Climate Risk and Opportunity Scenarios

CLC assessed transition risks and opportunities using the national net-zero emissions pathway. Physical risks and opportunities were evaluated with TCCIP data and the IPCC Sixth Assessment Report's SSP5-8.5 scenario. The TCFD risk classification framework was applied to identify transition and physical risks and opportunities, considering current and emerging climate-related regulations. Scenario risk factors were quantified for financial impact and likelihood based on established mitigation and adaptation capacities. Analysis showed that extreme climate events and long-term changes resulted in financial impacts of less than 0.1% of revenue.

*Note: For climate-related disclosures of listed and OTC companies, including climate change risks, opportunities, and response measures, please refer to Annual Report 2024 P40~P42

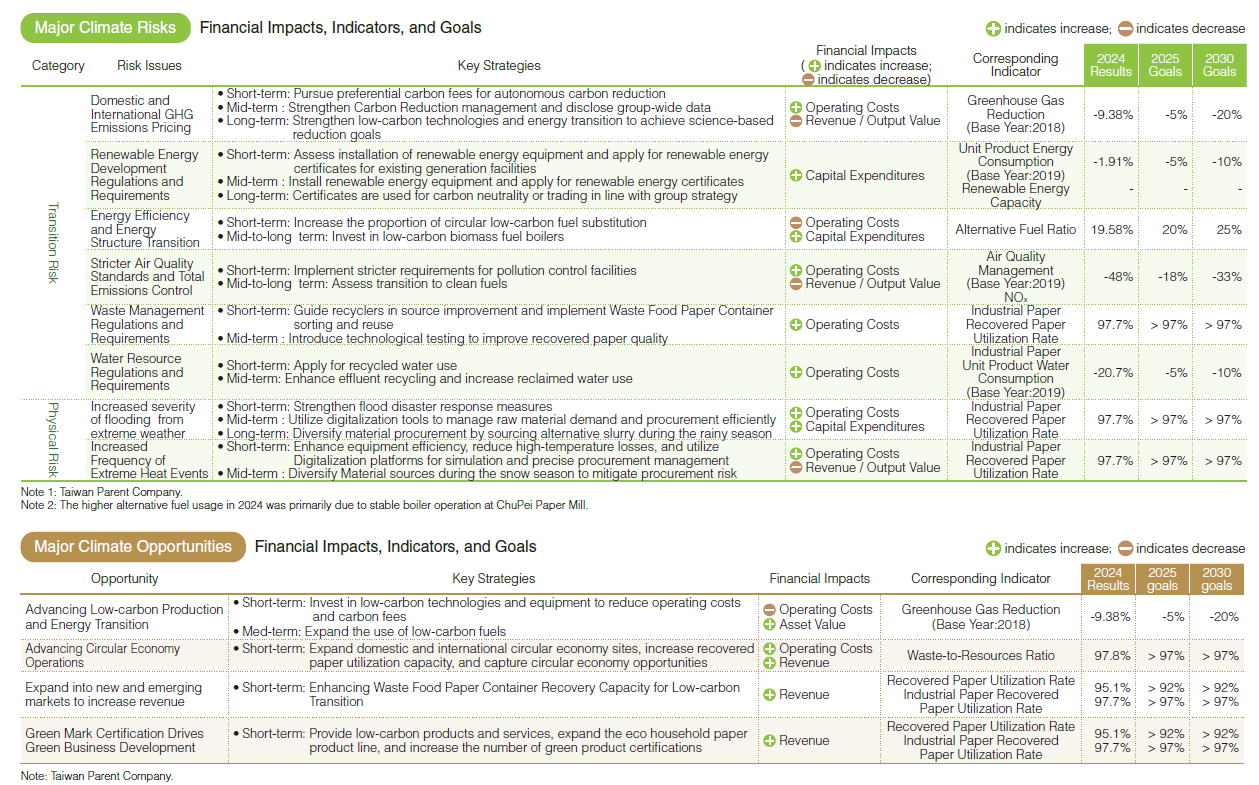

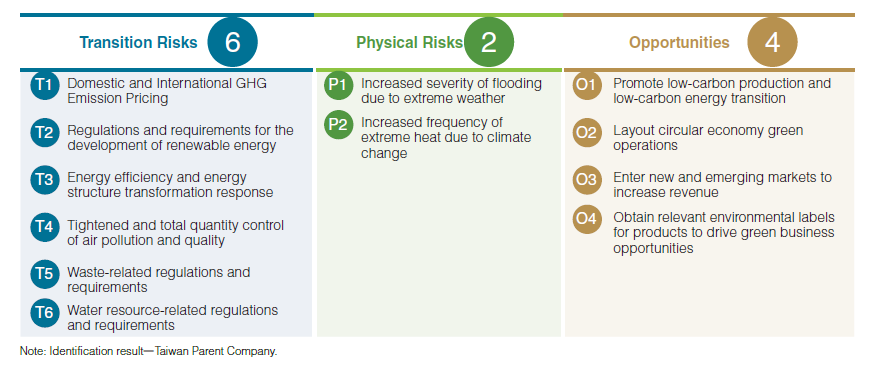

Major Climate Change Risks and Opportunities Assessment Results

CLC assessed short-term (1~3 years), medium-term (3~5 years), and long-term (5~10 years) risk exposures based on likelihood and financial impact, identifying 6 major transition risks, 2 physical risks, and 4 climate related opportunities with corresponding financial impacts. Targeted strategies were developed to strengthen risk management and operational resilience. TCFD assessments continue to cover domestic and overseas operations to quantify climate-related risks, opportunities, and financial impacts, supporting carbon reduction pathways, setting short-, medium-, and long term goals, and accelerating low-carbon development and climate adaptation strategies.

Major Climate Risk and Opportunity Strategies and Key Performance Indicators

CLC is advancing the Low-carbon Smart Paper transformation by leveraging digitalization to expand green production and sales, enhance energy efficiency, and reduce carbon emissions. The company implements four scientific carbon-reduction pathways: improving energy efficiency, developing renewable energy, advancing circular low-carbon fuels, and innovating carbon-negative technologies. CLC promotes circular reuse of agricultural and forestry residues and pursues the 3R PLUS Total Resource blueprint for carbon reduction. Under its risk management framework, CLC manages climate risks and monitors environmental performance through indicators such as greenhouse gas reduction, unit product energy efficiency, waste-to resources ratio, alternative fuel ratio, recovered paper utilization rate for industrial paper, unit product water consumption, and air quality management, with regular progress tracking and review.

GHG Emissions Decreased by 9.38% from the base year, Achieving Short-term Goals Ahead of Schedule

To align with national GHG reduction goals, CLC's Tayuan Paper Mill participated in the Industrial Development Bureau's pilot project in 2004. In 2005, CLC obtained the world's 1st ISO 14064-1 GHG inventory certificate. From 2006, CLC expanded the inventory mechanism to all mills in Taiwan and implemented company-wide emission reduction management. In 2008, CLC joined the Industrial Development Bureau's Voluntary Carbon Reduction Standard program and obtained Taiwan's 1st international VCS carbon credit certification. In 2016, CLC developed the TMS-II.013 Steam System Optimization methodology for the pulp and paper industry. In 2020, CLC registered the No. 1 Paper Machine Steam System Optimization Offset Project (Project Number: B00196) under the Ministry of Environment (Taiwan) Greenhouse Gas Offset Project, and will obtain a carbon credit of 64,708 tCO2e in July 2025. In 2022, Vietnam Binh Duong Paper Mill passed BSI verification and received the 1st ISO 14064-1 greenhouse gas inventory certificate in the Vietnamese pulp and paper industry, with the inventory management system extended to all domestic and overseas mills.

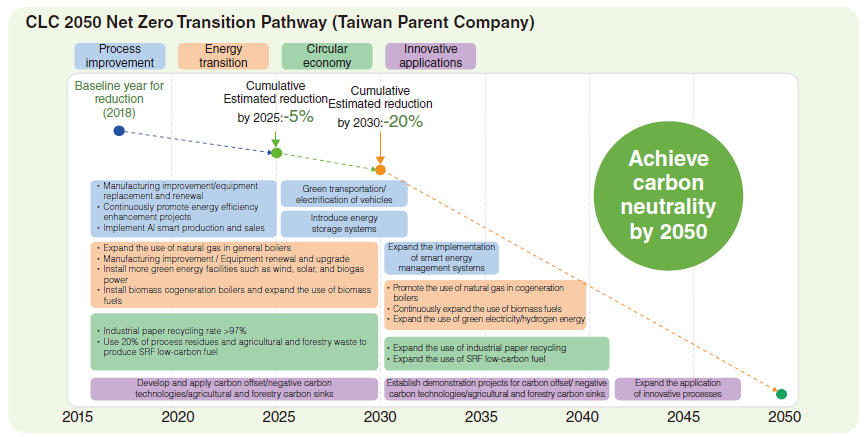

CLC set Scope 1 and Scope 2 GHG reduction goals for the parent company, using 2018 as the base year: 5% reduction by 2025, 20% reduction by 2030, and carbon neutrality by 2050. The Sustainability Committee and BoD oversee progress and planning quarterly, with annual evaluation of results.

Low-carbon transition is integrated into operational strategy, centered on circular economy, low-carbon green energy, and smart innovation. The S.M.A.R.T. low-carbon paper strategy includes Subtraction is Addition, Waste to Material, AI leads in Digital Transformation, Recycling drivers Circulation, and Technologies innovate Manufacture. Four scientific carbon-reduction pathways are implemented: improving energy efficiency, developing renewable energy, advancing circular low-carbon fuels, and innovating carbon-negative technologies. Tayuan Paper Mill participated in the Industrial Development Administration, Ministry of Economic Affairs' Industrial Low-carbon Transition Program.

Continuously reducing product carbon emissions intensity

With the full-scale operation of the ChuPei Paper Mill's biomass cogeneration system, product carbon emissions intensity was significantly reduced, and the company-wide alternative fuel ratio reached 19.58%. In 2024, CLC's Taiwan Parent Company reported GHG Emission (Scope 1 and 2) of 1,303,889.8472 tCO2e, a decrease of 70,056.3050 tCO2e (5.10% YoY) and a 9.38% reduction from the 2018 baseline, achieving the 2025 goals ahead of schedule. Carbon emissions intensity per revenue declined from 47.1727 tCO2e per NTD 1,000,000 in 2023 to 42.4388 tCO2e per NTD 1,000,000 in 2024, a 10.03% reduction.

*Note: 2023 revenue was calculated based on NTD 29,126 million; 2024 revenue was calculated based on NTD 30,724 million.

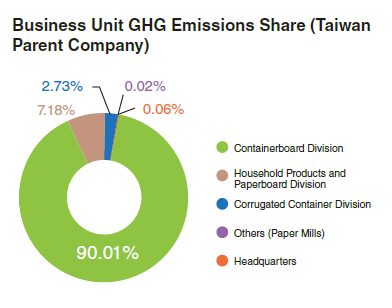

In 2024, greenhouse gas emission intensity decreased across business units: industrial paper was 0.836 tCO2e/tonne of paper (-3.38% YoY), household products and paperboard were 0.919 tCO2e/tonne of paper (-31.17% YoY), and Corrugated Container was 0.052 tCO2e/thousand m² (+0.93% YoY).

CLC's 2024 greenhouse gas inventory is conducted in accordance with ISO 14064-1:2018 and verified by a third party under ISO 14064-3:2019. Category 1 and Category 2 receive reasonable assurance, while Category 3 to Category 6 receive limited assurance. All categories have unqualified conclusions. Completion is scheduled for August 2025, with full assurance information to be disclosed by CLC Website - Download December 2025.

In accordance with the Sustainable Development Roadmap for Listed Companies, all 37 subsidiaries included in CLC's consolidated financial statements completed GHG Emission inventories in 2024. Subsidiaries' GHG Emission (Scope 1 and 2) totaled 690,659.2733 tonnes CO2e in 2024, with third-party assurance. CLC will continue to expand third-party assurance of GHG Emission inventories for overseas subsidiaries and targets completion for all subsidiaries by 2026.

CLC received multiple low-carbon sustainable transformation awards for its domestic and overseas plants. CLC participated in over 10 low-carbon sustainability forums with industry, government, and academia, and opened its plants for visits to facilitate stakeholder engagement and positive impact.

Product Carbon Footprint Management for Societal Carbon Reduction

Industry First: 6 Household Paper Products Awarded Carbon Footprint Label; Expanding to 12 Items by 2025

CLC advanced Low-carbon Transition, becoming the only company in the industry with 6 carbon footprint labels for household paper products, with plans to expand to 12 items by 2025 to increase green consumer options and support societal decarbonization. In 2024, the ChuPei Paper Mill's biomass cogeneration system was fully operational, reducing carbon emissions intensity for household paper products and paperboard by 31.17% and raising alternative fuel usage to 47.6%. Over 90% of products used recovered paper, remanufactured food paper containers, and scraps; the remaining 10% used FSC™-certified pulp. Multiple products received the Ministry of Environment (Taiwan) Low-carbon Product Award.

CLC applies scientific methods to verify carbon reduction results, conducts routine carbon management for major products, and advances carbon reduction initiatives aligned with the national net-zero transition strategy, Green Lifestyle, to increase its impact on a sustainable future.

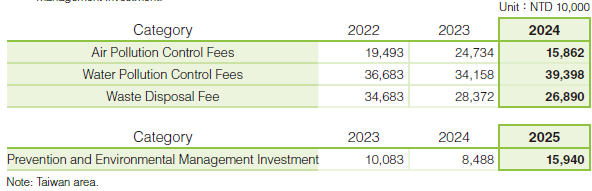

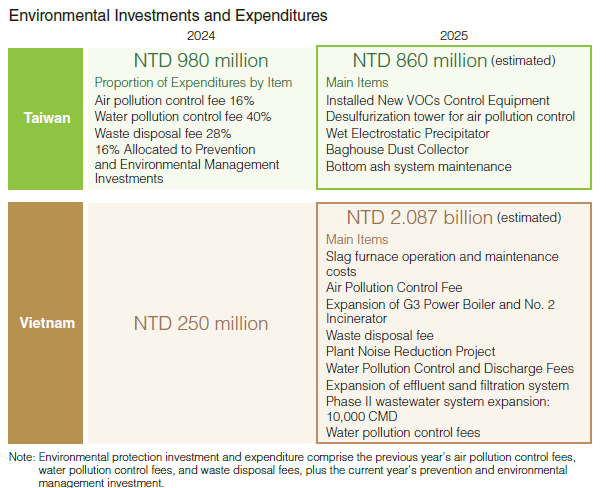

Environmental Management and Environmental Protection Expenditure

CLC categorized environmental expenditures and investments, implemented an environmental accounting system in 2001, and invested NTD 1.23 billion in environmental initiatives in 2024. CLC will continue to invest in enhancing environmental performance.

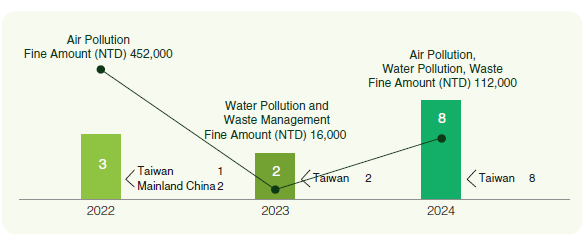

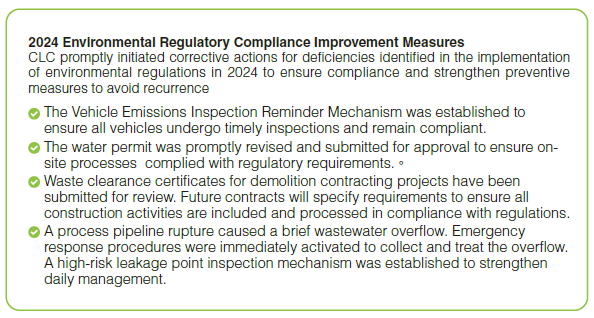

Environmental Penalties

CLC aims for zero major violations and continues to invest in air, water, waste, and odor pollution control, implementing management mechanisms to ensure regulatory compliance. In 2024, CLC recorded no major fines but identified 8 administrative oversights across 23 plants in the Taiwan area, including 4 air pollution, 2 water pollution, and 2 waste management cases, with total fines of NTD 112,000. All deficiencies have been corrected, personnel training has been enhanced, and preventive mechanisms have been established. CLC will continue to advance digitalization, strengthen staff training, optimize SOPs, and increase R&D investment in advanced equipment to improve environmental management and uphold its environmental commitments.