TNFD & Biodiversity

Paper for Nature: Biodiversity Vision

Each sheet of paper originates from forests. CLC applies the "secondary forest" concept by using recovered paper as material. Over 90% of products are made from recovered Material. CLC also sources 100% FSC™-certified sustainable wood pulp. Innovation and green principles are integrated into product R&D to deliver sustainable value and provide green consumption options.

No. 1 Paper Company in Taiwan

CLC Became a TNFD Early Adopter, Leading Industry Dialogue on Nature-related Risks

CLC advanced the Nature Positive Vision in response to climate change and resource limitations. In 2023, CLC signed to support the Taskforce on Nature-related Financial Disclosures (TNFD). In 2024, CLC became the 1st pulp and paper industry in Taiwan to join the TNFD Early Adopters and initiated natural capital risk assessments and strategic planning.

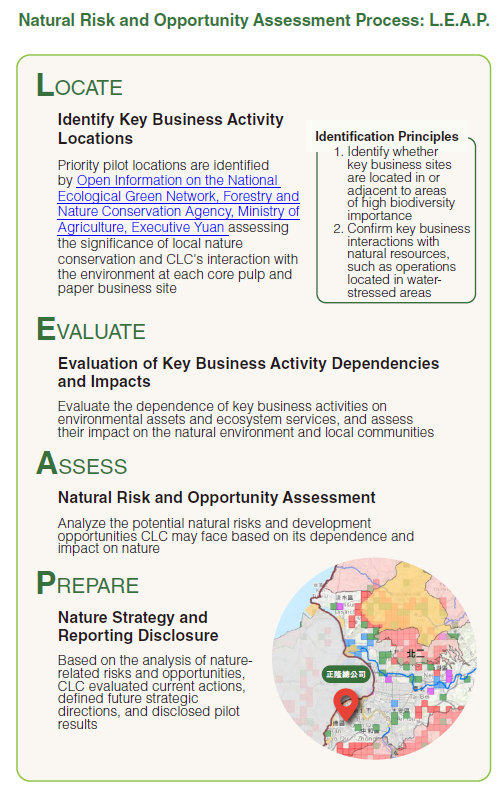

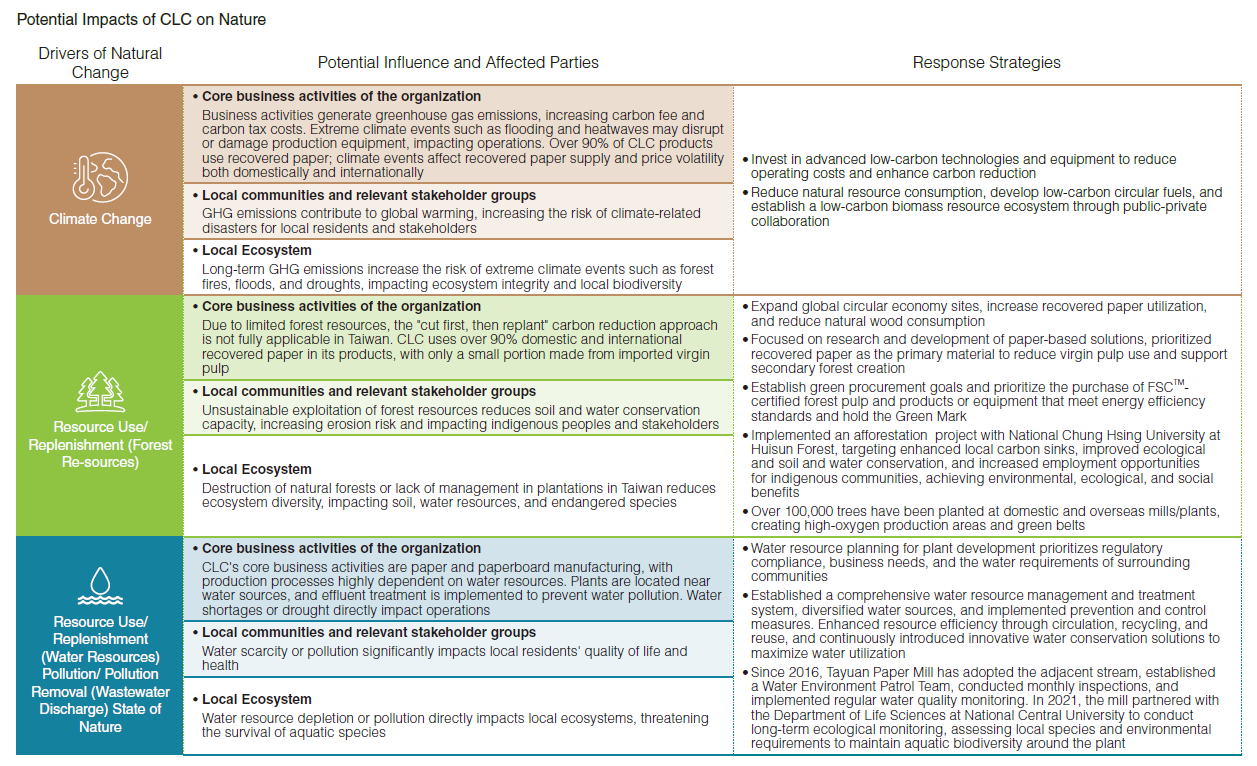

CLC adopted the TNFD Version 1.0 frameworks and initiated an internal L.E.A.P. analysis to comprehensively assess its dependence and impact on natural resources. CLC integrated industry, government, and academia resources to conduct natural capital and biodiversity research projects at its plants, strengthening risk management and corporate resilience. Beginning in 2025, CLC will disclose in accordance with the TNFD frameworks, focusing on governance, strategy, risk management, and metrics to ensure business operations are aligned with environmental sustainability, and will collaborate with industry partners to advance sustainable economic and environmental development.