CLC: New Low-Carbon & Green Energy Paper Company

Paper, the daily necessity tied up in our lives, is also an indispensable part of industrial and commercial packaging.

“Cherish Resources and Create a Secondary Forest.” Since the establishment of CLC in 1959, we have made good use of paper's cycle characteristics to reproduce various paper products made out of recovered paper using green paper production. The paper, or industrial paper to be more specific, is the greenest and most sustainable packaging material since it is reused, recycled, and renewed on a continuous basis. Moreover, the paper industry is also a typical and important circular economy industry.

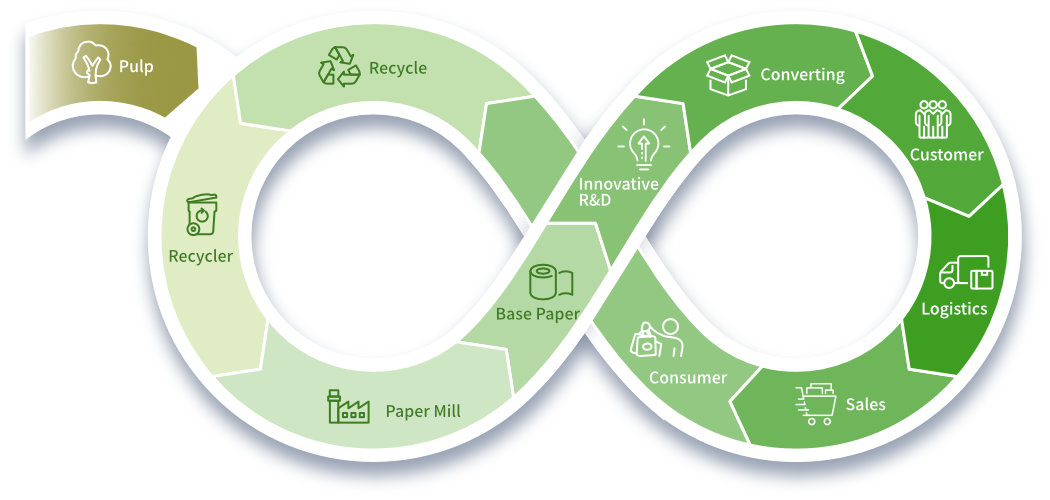

The life circle of CLC's products starts from the use of raw materials and then comes to R&D and design, green production, logistics and distribution, and then the end-consumer. Through the operational mode with papermaking and paper converting as the core, we provide a variety of products and comprehensive solutions for paper packaging to serve clients around the world. Meanwhile, we introduce advanced automatic equipment to improve the production and expand our green low-carbon production sites continuously, so as to strengthen the operational capacity and maintain our leading role in the market. CLC is currently the largest manufacturer of industrial paper products and paper containers as well as one of the largest paper companies in Asia.

To accomplish the vision of zero waste, CLC makes efforts to recycle the process residual material, promote the alternative fuel, and develop green energy via cross-industry cooperation, in order to actively transform ourselves into a new low-carbon green energy paper industry for the 21st century.

Secondary Forest. Circular Economy

For a product life circle which refers to phases of material use, product design, green manufacturing, logistics and distribution, and the end-consumer, we adopt a circular economy model of “renewable resource - paper making - packaging” to research and develop innovative and diverse green products and services, aiming at creating the circular benefits of secondary forests. In recent years, we have been actively integrating the total circulation of three major resources: products, energy, and water through the low-carbon S.M.A.R.T paper strategies: Subtraction-reducing resource consumption use, Materials-turning waste to energy, AI-smart production-sales, Recycling-reusing recovered paper, and Technologies-advanced processes to transform traditional factories into eco-friendlier smart and recycling plants.

With an annual conversion rate of up to 92.5 %, we recycle up to 40% of recovered paper weighing 1.6 million MT into eco-friendly products. Additionally, we replace fossil fuels with large amounts of solid recovered fuel (SRF) produced from the manufacturing process to reduce carbon of nearly 9.1 million MT for Taiwan each year, creating the largest scale of waste recycling in Taiwan. Through resource circulation and recycling, we provide green products for the market to indirectly mitigate the habitat damage from logging to retain about 5,233 Daan Forest Parks so as to build secondary forest and maintain biodiversity for Earth.

Note 1: The number is calculated based on the Muzha incinerator’s 196,728 tons of refuse disposal in 2019.

Note 2: Using each tone of recovered paper may save 20 trees from felling and reduce 5.8 tons of carbon emission.

Note 3: Assuming that there are 6,000 trees in a Daan Park.

Green Production.Save Energy and Reduce Carbon Emission

Continue to invest in advanced environmental equipment while developing green energy and alternative fuel, promoting recovery of process residual materials for use as resources and energy, and improving the integration benefits of energy resources. Introducing ISO management systems, performing greenhouse gas inventory, and encouraging waste recycling to save energy, reduce carbon emission, and mitigate climate change and environmental impact in an effective manner.

Innovative Circular Economy

First Paper Maker Completely Recycling Food Paper Containers

Implement the Total Circular Resource to Respond to the Plastic-Reduction Policy

To tackle the problem of waste food paper container disposal, we also believe that it is responsible for papermakers' responsibility to engage in recycling waste food paper containers. Therefore, we made advanced deployment by investing an "efficient film laminated paper treatment system" in 2018 to become the first company completely recycling food paper containers. In same year, started the "upgrading of recovered paper supply chain plan" and deepen the benefits of the circular economy. We supported over 167 recovered paper suppliers in Taiwan to upgrade. Reduced paper sludge by 50% and decreased the energy consumption by 10% by implementing source identification, and enhanced the profit and competitiveness of recovered paper supply chain. The plastic laminate is recycled into green fuel and eco-friendly building materials products. Pre-planned to help solve the growth of the takeout catering culture was driven by the epidemic and respond to the stop using plastic bottles policy in Taipei city in 2022 to realize benefits with a creative multi-win sustainability business model. With the goal of continuously deepening the recycling efficiency, the recycled bleached pulp line of Tayuan Mill, which will operate in 2023H1.

Pulping for document destruction reduced carbon emission

by 61,370 MT and saved 212,000 trees

In 2013, we began to provide free document destruction service by exerting our pulping expertise in paper recycling to repay society through the innovative use of our experience recycled paper papermaking. By doing so, we prove the possibility of reducing environmental impact while achieving economic efficiency. Over the last 10 years, we have helped 400 partners, including government entities, listed companies, banks and insurers, and national defense units, to destroy 10,581 MT of confidential documents through pulping for free to recycle paper for producing over 45 million packs of eco-toilet tissue to create win-win.